Streamline planning, execution and inspection in SAP EWM

The word “wave” initially brings to mind a sunny day at the beach – salt in the air, the wind blowing through your hair. The bad news is that Wave Management is not a relaxing pastime in the Maldives. The good news: It can trigger similar feelings of happiness among warehouse managers and “KPIers”, as the use of Wave Management in SAP EWM optimizes the planning, execution and checking of warehouse activities. How? We’ll take a closer look at that below.

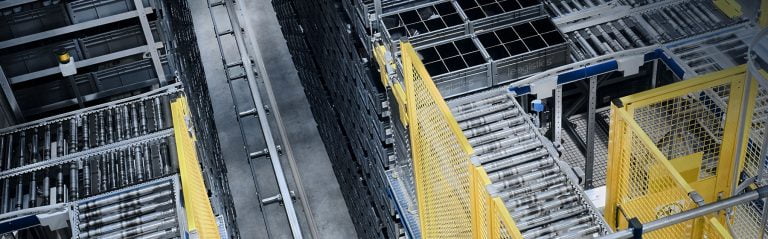

Bundle deliveries with Wave Management

In warehouse logistics, Wave Management refers to the grouping of warehouse requests that represent the need for a movement for a specific quantity of product. This includes movements of production supply, replenishment or shipping. The latter will be explained using a highly simplified example:

For shipping, delivery orders are used that contain one to n items. Each item results in a warehouse request item.

A suitable wave is determined for each warehouse request. The delivery orders (circle) themselves are not taken into account at first, since the warehouse requests are considered separately from them. This gives us the following graphical representation:

Grouping warehouse requests into order packages

Many different subsets result in a large quantity of different warehouse requests, which are grouped according to the same criteria in the next step. In the context of delivery orders, the route is often used as a criterion. Other criteria such as delivery type, warehouse process, ship-to party or planned goods issue date are also possible.

Accordingly, all warehouse requests with the same route (or the same delivery type, etc.) are bundled into a new subset. However, warehouse requests located within a subset (route) do not necessarily end up in the same wave, as further detailing is possible on the basis of a wave template. The latter then deals with the “how” and “when”, whereas previously only the worklist of a route was known. The wave template contains both the properties of a wave and the different wave options. The conception of a wave template is done with the help of certain condition sets, by which a route is firmly linked to a wave template.

Delivery location, timing and capacity limits define the waves

For the route “Standard shipping Germany”, for example, it was specified that an automatic release takes place for the waves formed at the defined start time. In addition, three trucks leave the warehouse per day (at 12:30 pm, 05:30 pm and 7:30 pm) for this route. As a result, three wave options were stored for the wave template. Based on this definition, the warehouse requests can be divided into different waves to ensure simultaneous execution of the required warehouse activities per truck. Furthermore, for each option it is defined up to which point in time (cutoff) further warehouse requests can be added to a released wave.

Define the start and expected end with a wave

If different wave options are used on the basis of defined times, the determination of a suitable wave option is carried out taking into account the date type “leaving the yard” in the delivery order.

Consequently, not only the start but also the expected end is defined in a wave to enable backward calculation. This means that the end of the wave must be before the corresponding time in the delivery order, but for the best case as (time-)close as possible. Thus, the warehouse requests of the delivery orders are assigned as follows:

In the above example, each wave option results in exactly one wave, since the wave options do not contain capacity limits. The latter can be used if the workload distribution would otherwise fluctuate too much throughout the day.

When the warehouse request is assigned to a wave, initially no worklist is generated for the personnel to be executed. Only with the manual or automated wave release the executable warehouse tasks are created. A warehouse task defines the goods movement of a handling unit or a product in a defined quantity.

Bundle and prioritize deliveries with wave management.

In addition to creating waves based on routes or time criteria, it is also possible to bundle processes. This means, for example, that warehouse requests for less important processes, such as replenishment and warehouse reorganization, can be collected and released at a later hour. In addition to priority, it may also be relevant that certain warehouse activities only deliver significant added value in terms of cost/benefit when a higher number of warehouse requests are released.

Wave Release - now what?

As already explained: The creation of waves does not yet result in an executable worklist for the warehouse workers. Initially, wave management only serves to bundle warehouse requests with the same criteria and ensures their execution at the right time by means of static calculations.

Consequently without further precautions with wave release the production of the warehouse tasks would take place, without forming smaller and/or meaningful work packages (warehouse orders). In the worst case, the entire wave or truck could end up in a warehouse order that can only be processed by a single resource. This has to be prevented, which is why warehouse order creation rules are used. These are sets of rules that determine how work packages (warehouse orders) are to be created. A warehouse order contains several warehouse tasks.

Consider warehouse order creation rules

We are here for You!

With Wave Management, SAP EWM provides a foundation for improving the planning and monitoring of all warehouse activities. By ensuring that goods are available in the staging area before a truck’s departure time, an improved order fulfillment rate can be achieved. In addition, there is full transparency for the warehouse operations desk on the current wave progress.

What must not be forgotten, however, is that when viewed in isolation, this is a very static scenario, which is why the entire planning and any automatism can already be upended by a delayed truck. The goods would then be in the staging area, the gate would be blocked – and the truck would not yet be in sight. This can only be remedied by holistic supply chain execution, in which real-time data is used to continuously optimize planning during ongoing operations.

In the second part of our blog series on Wave Management with SAP EWM, we will inform you about such optimization options with the help of holistic supply chain execution.

If you have any questions about this or other topics in this blog, please contact blog@leogistics.com

Julian Richter

Senior Consultant SAP Logistics

Avoidable pitfalls in production integration in SAP EWM

With The Introduction of S/4HANA, Does SAP WM Soon Belong In The “retirement home”?

SAP WM Versus SAP EWM – All Pros And Cons (2/2)

SAP WM Versus SAP EWM – All Pros And Cons (1/2)

3 scenarios to connect your SAP EWM to third-party systems

SAP S/4HANA 2020 FPS01: Many New Features in Stock

SAP S/4HANA 2020 FPS01: SAP TM and EWM Improve Interface Communication

The significant of reporting in SAP S/4HANA extended warehouse management

The SAP standard does not hurt!

BLOG &

NEWS

Up-to-date news and blog posts from the world of intelligent supply chain management

.