On October 13 and 14, the Logistics Summit 2021 took place in Berlin – a long-awaited opportunity to exchange ideas with industry experts on site. Our leogistics team also represented our logistics platform and our software solutions at the trade fair stand.

Numerous visitors and discussions are proof enough for us that we are tackling the future issues of logistics and supply chain management for our customers in the right way.

On day two, I had the pleasure of discussing supply chain transparency on the main stage with leading logistics managers René Langrock from mymuesli, Gerald van den Eijnden from Molex, Tobias Walther from REHAU and Joachim Schaut from DB Schenker: How do experts already manage to get real-time data from their various service providers? Because this is a basic prerequisite for keeping an even better eye on and controlling supply chains in the future.

A supply chain control tower alone does not improve supply chains

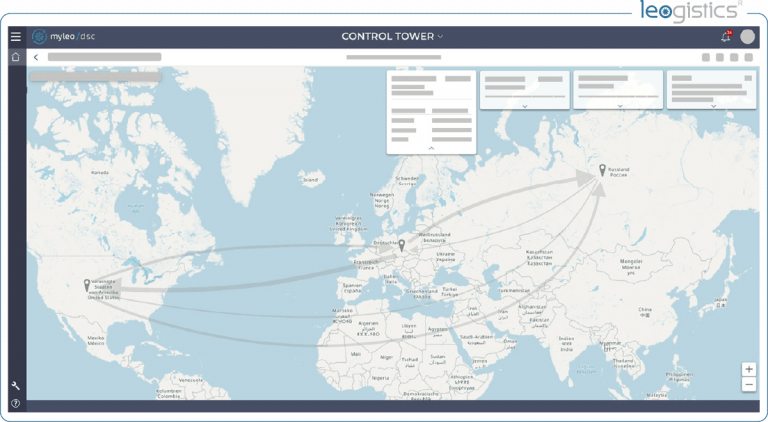

In today’s global economy, many companies find it difficult to keep track of their inventories, orders and transport processes. An instrument such as the Supply Chain Control Tower can help companies to view their own logistics as value-adding and make a valuable contribution to answering a wide range of logistical questions: Is business going well? Are current inventories and capacities sufficient? How can requirements from sales etc. be mapped in the supply chain? Can just-in-time deliveries be processed? And what data is needed to resolve all this?

One thing is clear: Even a supply chain control tower – even with the greatest scope and know-how – cannot compensate for delivery fluctuations. According to the experts, the triad of organizations “people,” “digital and physical processes,” and “software” must be dovetailed in such a way that supply chains can be monitored with as little or no media disruption as possible.

But how can the acceptance and consent of service providers, i.e., people, be achieved to work together in a network? To date, skepticism and concerns about control still block the seamless exchange of data.

Smart decisions are based on data

In order to proactively counter fluctuations, real-time data and targeted analysis of these are required. Only when the data quality – and the understanding of it – is right, can the information collected be enormously useful. Because nowadays, the difficulty is no longer in collecting data, but rather in weighting it correctly and fishing out the relevant information from the seemingly inexhaustible stream: Which information is at all crucial for one’s own delivery?

In order for important data to be delivered to the control tower, the added value must first be made clear to all parties involved. Because another central question is for whom in the company is which data important, for example, the warehouse, production, transport or customer service departments?

Therefore the data should not only be analyzed and communicated from the producers’ point of view. It is just as important to communicate to the forwarders and their subcontractors where their advantage lies in sharing data. Of course, the aim is not to control the forwarders, but to look as far into the future as possible in order to be able to manage crises, reduce supply bottlenecks and ensure production reliability.

This also brings competitive advantages for the forwarding companies: In this context, the reduced throughput times for the delivery of goods, the reduction of the internal planning effort, since the frequent “calling after the goods” is eliminated, as well as the linking of notification, transport order and time slot booking should be mentioned. The linkage improves the information situation for forwarding agents and customers alike, especially in inbound! In addition, freight invoices can be reconciled easily and unbureaucratically online, which saves valuable resources and is easy on the nerves.

Counteracting supply bottlenecks and production bottlenecks through connected collaboration

Both the pandemic and the current resource shortages in many industries are boosters for connected collaboration between supply chain partners. This is because many have realized in these times the need for supply chains – and production supply in particular – to become more resilient and more sustainable. To counteract tight markets, there seems to be no way around supply chain automation. In view of the shortage of materials in many industries, there is a great focus on inbound in particular.

However, the answer to the question of how all stakeholders can be brought together to appropriately enrich a supply chain control tower with data is still missing. No wonder: The large number of stakeholders in the supply chain – in some cases up to 25 in number – makes automation and data delivery so difficult – even more so across several different modes of transport up to the last mile. After all, even the most stable supply chains still experience breaks from time to time.

The crisis as a driver

he Supply Chain Control Tower is perceived by the industry experts at Logistics Summit as an important decision-making aid that proves its worth not only in times of crisis. However, it is often the case that only natural events such as a volcanic eruption in Iceland that paralyzes European air traffic, a widespread storm or the Corona pandemic draw attention to how fragile our global economy actually is. But even data that is not complete, but provides a trend over a longer period of time, helps to make decisions and manage risk. Thus, for the future, more understanding between stakeholders is needed. One goal should be to improve communication in such a way that it becomes clear to all stakeholders how they work interdependently with each other.

The control tower should be standardized and, in addition to master data, enriched with news, weather data, economic information and supplier risks so that all parties involved have insight into the supply chain at all times. The supreme discipline would be to offer end customers the opportunity to look into the system themselves, in order to be able to view the delivery time of the ordered goods on his own initiative across all supply chain levels and also to transfer it to his own system world. However, data quality and data standards would have to improve considerably in order to guarantee a positive user experience.

We are here for You!

It pays to bring supply chain stakeholders to the table, to connect, and to ensure understanding in order to counteract fluctuations in the market. This road will not be an easy one, but the need is obvious – today more than ever.

We support you in making your operational processes more efficient, transparent and cost-saving, thus strengthening your supply chains. Have we piqued your interest? Then please feel free to contact us.

If you have any questions about this or other topics in the blog, please contact blog@leogistics.com

André Käber

CEO leogistics GmbH

Successful Application Development with Design Thinking

Our Straightforward Customer Service For Your Concerns

The Future of Yard Management: Contactless And Digital Yard Management

Container management: Do you still have all containers in stock?

Transportation management systems are changing

How to overcome obstacles!

I develop a voice assistant for digital logistics solutions

How to optimize the check-in and check-out process

Goodbye Scheduling Chaos: Stay On Top Of Things

BLOG &

NEWS

Latest news and blog posts from the world of intelligent supply chain management.