More dynamics and transparency for your warehouse

Home Goods Issue

Follow strict rules when picking goods.

Optimized warehouse processes extend to loading

In order not to lose any time and to get trucks and containers to be dispatched from the yard as quickly as possible, it is essential to ensure a smooth outbound goods process and to use software to support employees during the picking as efficiently as possible. It is often advisable to combine several orders into so-called waves, thus speeding up picking by consolidating customer orders. These waves can also be parallelized, allowing several trucks to be prepared at the same time, for example.

Meet your individual requirements!

The basis is the picking strategy. In addition to the picking principle (FIFO, LIFO, etc.), this can take into account special features such as batches, serial numbers, full or partial pallet picking or exclusive picking from fixed locations. The system suggests the correct storage location for picking the requested quantities and guides the user through the process.

- Picking processes have often been part of major optimization projects in recent years. The possible strategies differ, for example, in "goods to man", "man to goods" and "multi-order".

- During consolidation and packing, a warehouse management system can split the picked quantities into the individual orders. This ensures that the orders contain only the requested materials and quantities and can also be processed only by resources that meet the qualification profile for the activity and use the appropriate picking equipment.

- The integration of production supply is an important part of the goods issue processes for many clients. This means that picking from the warehouse is triggered automatically when an order is released and can be carried out by an employee.

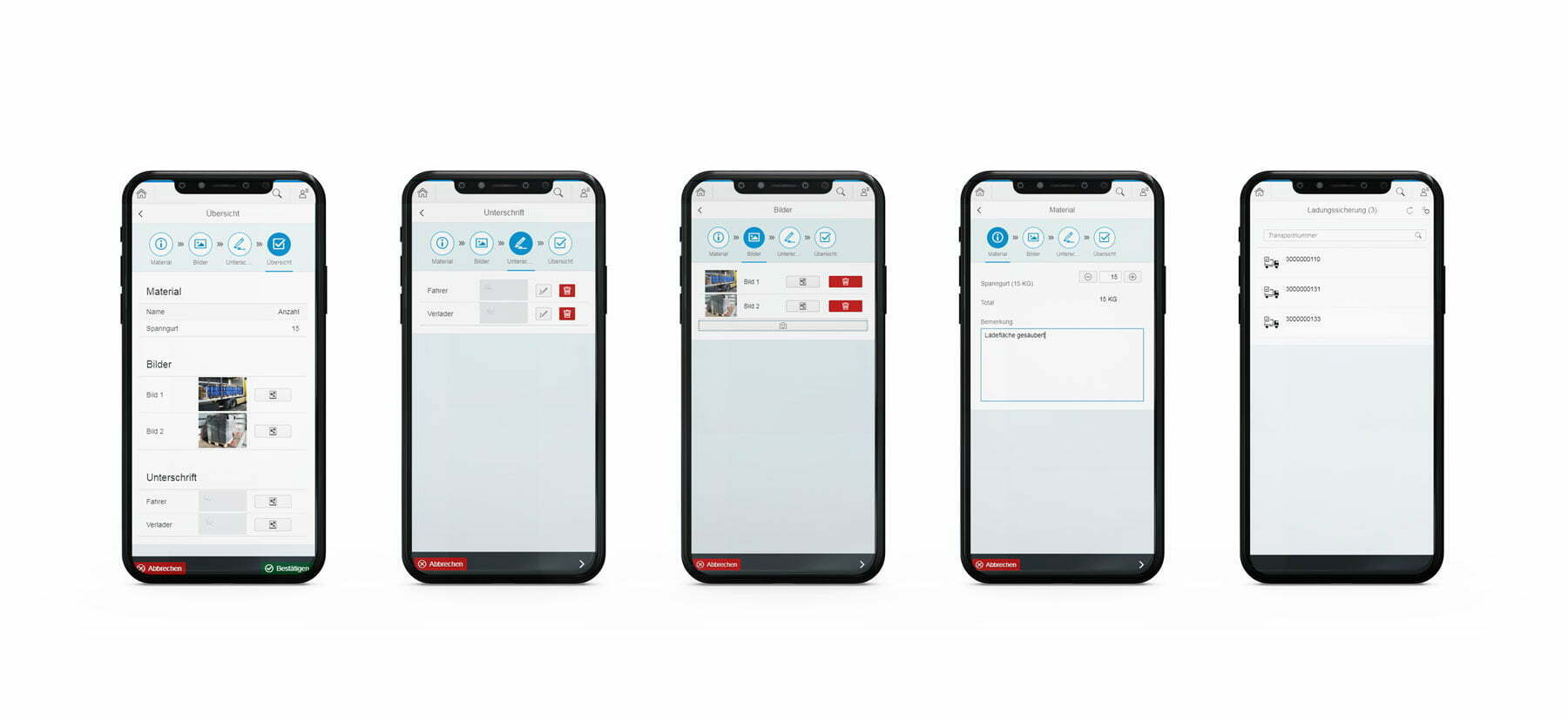

Load securing as a component of truck handling

Legal requirements for the implementation and documentation of load securing are diverse and depend heavily on the material to be loaded. With the help of a mobile device, you can easily document the securing of the goods to be loaded in accordance with legal requirements.

Loading equipment

Maintain loading equipment as master data, record used loading equipment and add it to the load weight.

Documentation

Document the load securing by means of a photo and protect yourself against recourse claims for missing or defective goods.

Digital Signature

With digital signature of the loader and the driver, it is always possible to trace who has carried out the load securing.

WE RECOMMEND FROM OUR PORTFOLIO

LEOGISTICS SOLUTIONS AND SERVICES

With our expertise and our comprehensive range of consulting and software services, we are your partner for the implementation of your individual logistics requirements.

SAP Extended Warehouse Management

Warehouse Management

leogistics Yard Management

Digital Supply Chain Management

Understanding the Role of SAP Business Technology Platform in Modern Logistics

TM in SAP S/4HANA Public Cloud

Innovations in Bulk Material Logistics: Harmonizing Automation and Planning

Optimizing Warehouse Logistics with AI and Data Analytics

Why Digitization and AI Will Determine the Success of Warehouse Logistics in the Future

Great Flexibility for Your Transportation Processes with Conditions in SAP S/4HANA TM

“The yard is the central hub for our entire supply chain planning”.

The Warehouse as a Valuable Part of the Supply Chain

SAP S/4HANA Fully Activated Appliance (FAA) At A Glance

BLOG &

NEWS

Latest news and blog posts from the world of intelligent supply chain management.

CONTACT US

Get in touch

We’d be happy to provide you with strategic advice on identifying optimization potential and developing a holistic target picture for your future logistics processes.