Automation as a driver for smart port logistics

Do things right and talk about it. Share gained information with others and benefit from it together. Save time and money by a trustful use of data and working together. Smart Port Logistics stands for all this.

We show you the potential of automation and smart port processes and offer insight into our leogistics Port solution for mapping maritime processes in SAP.

Why is the degree of automation important?

The formation of networks and alliances with the aim of exchanging information makes logistical processes more comparable. In a digitalized and globally networked logistics system, benchmarking is facilitated and the competition has figures available on dispatch and handling times. New logistic alternatives are emerging, such as the new Silk Road for landside traffic. Competitive pressure is increasing.

The degree of process automation can be a unique selling point in order to save costs and time and increase process reliability.

Data form the basis of automation

Digitalize your processes to have relevant data available for automation measures.

The easiest way to ensure real-time information about loading and discharging operations, inventory changes and the availability of specific freight units for further processes is to use mobile devices. This also includes information for cost and revenue analysis, which can be transferred promptly to a billing module. Finally, real-time information on cargo movements allows the measurement of service level agreements and progress in cargo handling.

Draw conclusions from your cargo movements

A large variety of information can be recorded during cargo handling in the port:

- Where was a unit picked up and dropped off?

- Who carried out the activity and when?

- Which equipment was used?

If the data from process execution and billing are recorded in detail, interesting conclusions can be drawn for you:

- Transferred to an artificial intelligence, ideal contract designs can be derived from the data.

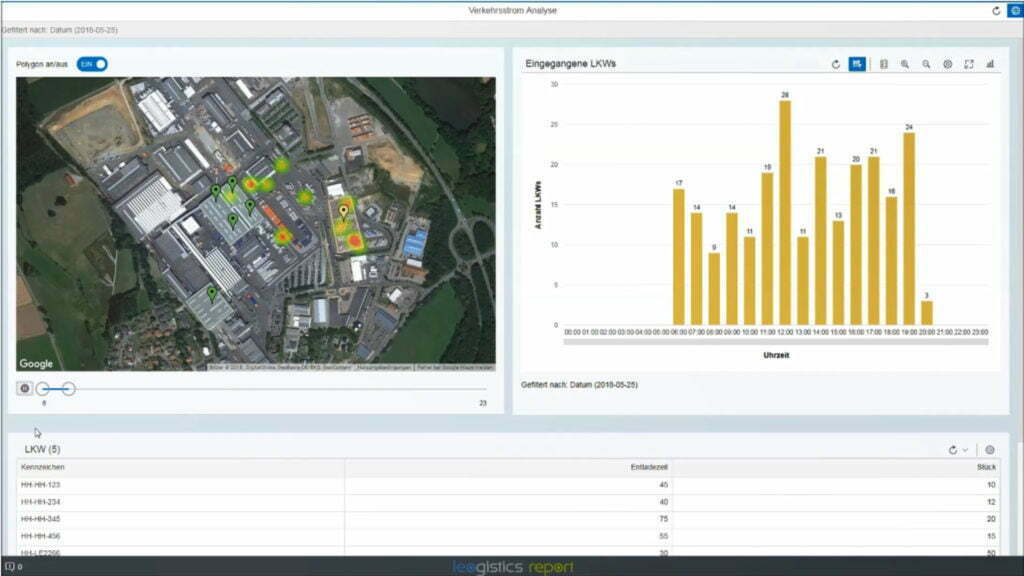

- You can create heatmaps to identify bottlenecks during loading and unloading operations. Is there an increase in traffic at certain points? Are transport routes congested at neuralgic points on the quay or on the way to the warehouse?

Automation possibilities using the example of dispatching

As the heart of the port logistics processes, we first want to examine the loading and unloading processes with regard to their automation potential.

| Verknüpfung von Prozessen | Sind Informationen aus Tracking Devices oder Telematik-Einheiten zugänglich, lassen sich Bereitstellprozesse automatisieren und vorbereitende Arbeitsmaßnahmen triggern. |

| Der HUB-Vorgang | Bei Hubvorgängen kann ein Container gewogen, und so überprüft werden, ob das im Bill of Lading angegebene Bruttogewicht stimmt. Es kann eine Aussage darüber getroffen werden, ob die Box tatsächlich die angegebene Ware enthält. Auch Zustandsüberprüfungen lassen sich während des Hub-Vorgangs mittels technischer Erweiterungen automatisieren. |

| Tracking von Cargo Units | Das höchste Potential, Cargo Bewegungen zu optimieren, liegt im Tracking der Units. Um den Prozess von Empfang über Lagerung bis zur Verladung möglichst stark zu automatisieren muss ein geeignetes Device zur elektronischen Lesbarkeit bereits frühzeitig an der Cargo Unit angebracht werden. |

Optimisation potential in truck handling

In addition to the handling of ships, the handling of trucks also offers opportunities to save costs and above all time through automation. Two factors can negatively influence the processing speed of trucks: Complex check-in processes due to security checks and loss of time when calling up from waiting places to the loading or unloading zone.

How to deal with these problems?

- The check-in process can be standardized as far as possible and carried out as a continuous process on a tablet. Predefined questions form the basis of the verification and signatures are executed directly on the device.

- Use the check-in and check-out timestamps to calculate the current truck processing time and share it in a portal. Your network partners are always thus informed how much time they need to plan for the next visit to your terminal.

- Self-check-in terminals, where the driver registers with a turn-in, turn-out or order number sent in advance, shorten the check-in time, especially at peak times, as several entries can be made at the same time.

- Video gates can inspect containers for damage during check-in and check-out, and store photos to counteract claims for recourse (has the damage occurred in the terminal?) with regard to correct handling afterwards. Using OCR technology, cameras can recognize license plates and container numbers and thus further automate the process in order to come one step closer to the goal of the “smart” port.

Automate your railway processes

Similar to truck handling, port railway processes can be improved through partial automation, especially at arrival and departure. In addition to electronic track occupancy overviews and electronically available shunting orders as well as mobile feedback of wagon movements, the following checks should be mentioned:

- Automated camera recording of wagon numbers

- Train sequence check by measurement of centre distances

- Mobile comparison of wagon conditions with electronic damage list

Smart port logistics with leogistics port

Automation and the conversion to “smart” processes require the right IT infrastructure. For this reason we would like to introduce our port logistics solution leogistics Port to you.

Our SAP-based solution for terminal and port logistics includes functionalities for the planning of maritime logistics processes, the management of ship arrivals, the handling of discharging and loading processes, inventory management and the billing of warehousing and services. leogistics Port is rounded off by further components of leogistics d.s.c for the areas of truck yard control, port railway and reporting.

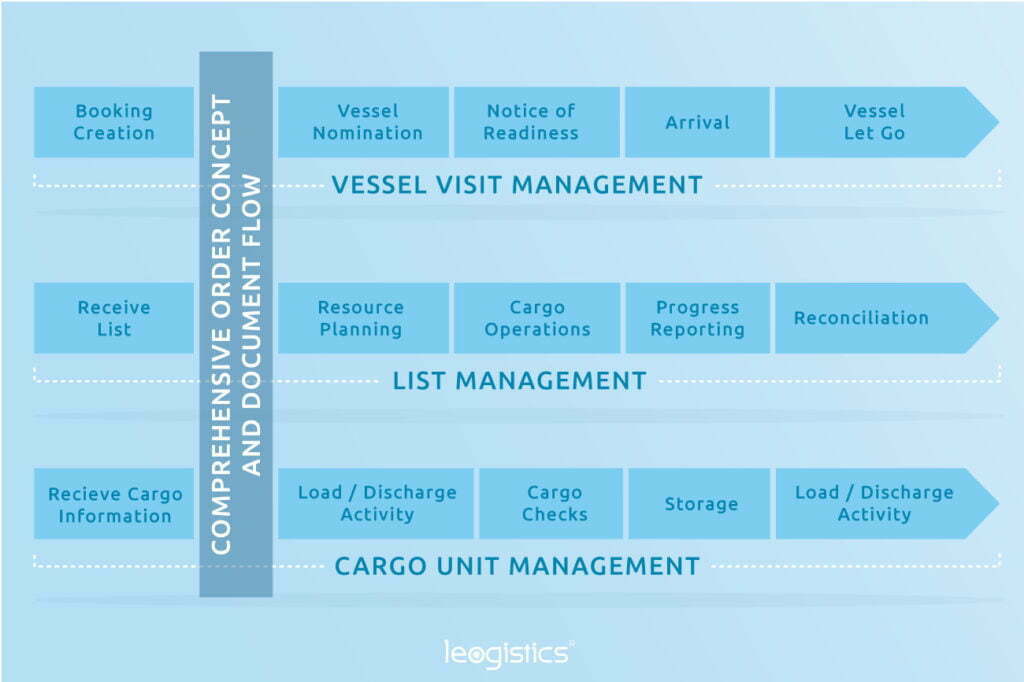

The basis for mapping logistical processes in leogistics Port is the individually definable order concept, which can map processes and information at various hierarchy levels.

Making information available and processes plannable

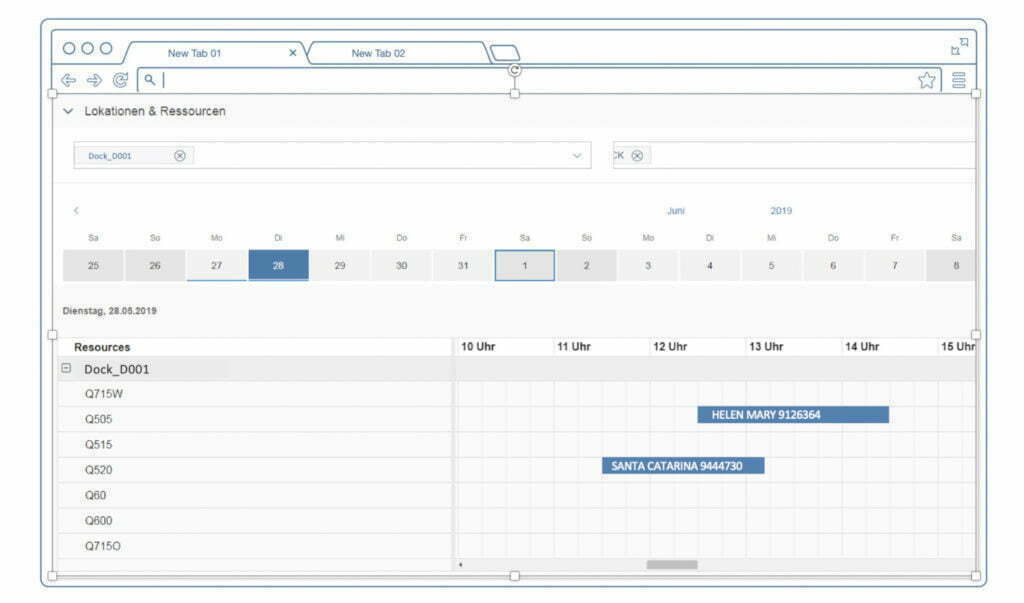

In order to become aware of possible bottlenecks in passage planning or with the required equipment at an early stage, it makes sense to combine ship arrivals, schedules and available resources in one planning Gantt.

Berth planning in the Gantt makes it possible to identify bottlenecks at an early stage and to recognise negative effects early on when planning new berths or re-planning. If corresponding contract information is stored in the system, estimated demurrage costs can be shown in the berth planning.

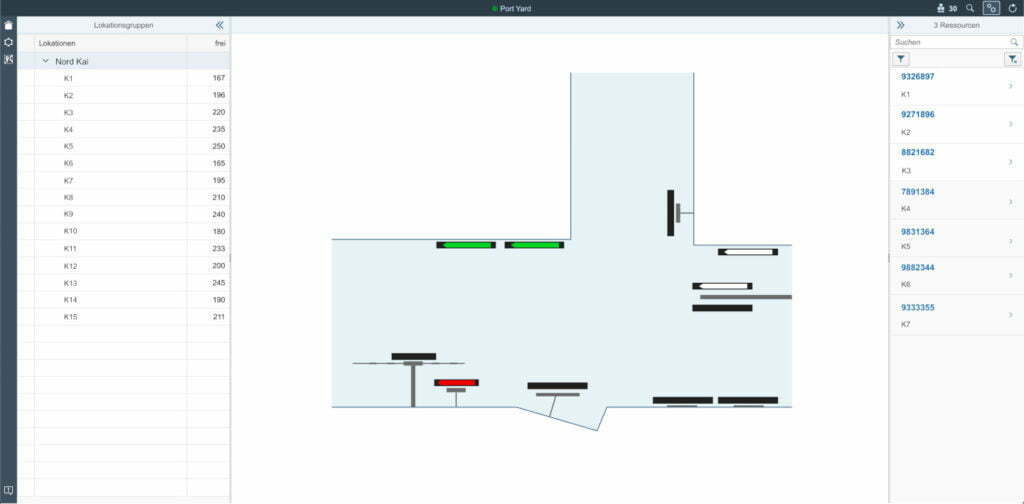

Live information and visualization

Where are the goods to be loaded? How many trucks are currently on the terminal? Is my berth already available?

Like exact coordinates for cargo units, the visualization of means of transport can also increase transparency in the port. AIS information for tracking ship positions, sensors on jetty’s and tracking devices on trucks enable exact localization and thus automation of processes to the greatest possible extent. Waiting and idle times can be avoided if the individual movements are clocked and orchestrated by IoT-controlled process management.

It is advisable to track the progress of ship handling in detail in order to check one’s own performance, but also to demonstrate it to customers. Detect plan/actual deviations at an early stage and initiate countermeasures.

Invoicing and margin calculation

The greatest complexity in the billing of logistics and maritime services in the port environment lies in the often complex and historical contracts between logistics service provider and customer. As a rule, the payroll bases are not very standardized and have individual features that need to be considered when preparing the payroll run. The continuous document flow with leogistics Port already shown makes it possible to get a grip on the variety of possible billable services and to automate the process as far as possible.

What measures should you take?

Current market changes as a result of the formation of networks and alliances as well as new technical possibilities (such as IoT, Blockchain and KI) have a strong impact on current and future IT projects in the maritime environment.

The switch to Industry 4.0 represents a major challenge for port and terminal operators: Adaptation measures to new ship sizes require an enormous amount of time and capacity, which are then lacking for necessary digitisation projects. For terminal and port operators, there are a number of possible measures, most of which have to be located in adjustments to the current IT infrastructure. We are happy to carry out an inventory of existing processes and IT systems in your logistics with you and derive concrete steps to make your processes “smart”.

If you have any questions about this or other topics on the blog, please contact blog@leogistics.com.

Jan-Philipp Horstmann

Michel Templin

Consultants SAP Logistics