How modern industrial railways plan their operations

Plant railways form the logistics link between mass-capacity rail transport and a company’s in and outbound goods. Nevertheless, these railways are typically operated with a lot of retro charm; however, with little IT support, they lack integration with other areas of the company.

While other departments have been using optimal scheduling, automated resource planning, and integrated planning processes for years, plant railways have to act on call and carry out their shift planning with spreadsheets.

In this blog post, we’ll look at the possibilities of integrated and automated planning for this “logistical link”, exploring how innovative solutions can bring our plant railways into the digital age.

Integrative shipping processes and empty wagon planning

The preparation of deliveries by the shipping department is usually carried out in an ERP system. With the ERP process already in place, a digital dispatching system for the plant railway can be connected. The dispatch time is automatically scheduled based on the point of departure, the dispatch conditions, and the route and characteristics of the material to be sent.

Communication with production and logistics takes place via workflow. The time of production and availability of goods are also included in the planning.

By combining dispatch times and wagon data, the system can determine optimal wagon transitions.

The advantages of operational planning in the factory railway environment

Incoming wagons are directly reloaded after unloading on the basis of the system proposal, returned to the rail transport operator or stored as empty wagons at the holding sidings and reserved for future shipments of goods. The use of forecast models support the shunting planner in determining future wagon requirements, preventing transport requirements from being missed due to a lack of wagons.

Planning also prevents excess storage of empty wagons (surplus cover by wagons of a certain type). Along with traditional planning algorithms in SAP ERP (based on seasonal forecasts/trend recognition), project-specific planning algorithms with special requirements can be integrated into planning process, e.g., machine learning.

The aim of intelligent planning is to use each individual wagon economically and to optimize the costs of wagon hire.

The mapping of integrated processes

Integration with the shipping department gives the plant railway access to the entire material master of the goods being shipped. This enables the planner to view the specifics of the goods, optimally preparing the wagon loading. In many cases, the system is able to create a load design automatically.

When dangerous goods are shipped, integration also offers the option of observing rules and regulations from SAP EH&S (Environment Health and Safety) in load space planning.

Access to the material master offers a further advantage to operations—the system can create CIM bills of lading, completely automated.

Resource planning

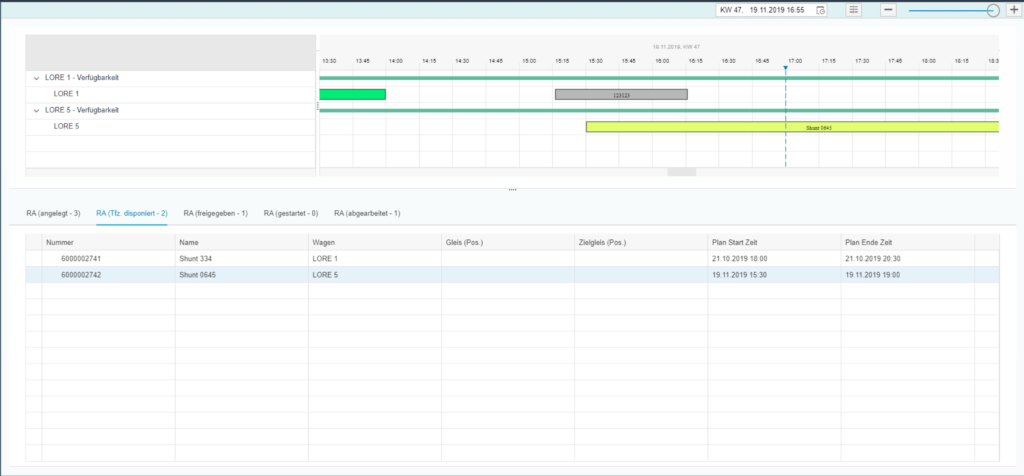

An integrated scheduling system not only supports the shunting scheduler in operational personnel and engines deployment planning, it also independently provides suggestions for optimum resource deployment.

By detailed mapping of future train entrances, exits, and loading point operations, the system can determine the number of shunting employees required. Different roles such as shunters, shunting ladders and wagon service officers are considered.

Personnel planning observes company regulations, which are systemically mapped in the form of rules and regulations. Depending on those rule sets, the determined roles can be filled automatically with specific employees—or a proposal for the personnel resource planner can be generated.

Employees are stored in the system as resources, with master data representing individual training, qualifications and availability. The final shift planning is also reported back to SAP ERP, enabling further workflows.

Locomotive planning

The planning of locomotive deployment is based on the same principle: planned wagon movements result in the required traction power. Shunting orders are filled with specific shunting engines. The traction units are reflected as resources in the system and the master records contain regulations as well as planned maintenance and inspection intervals.

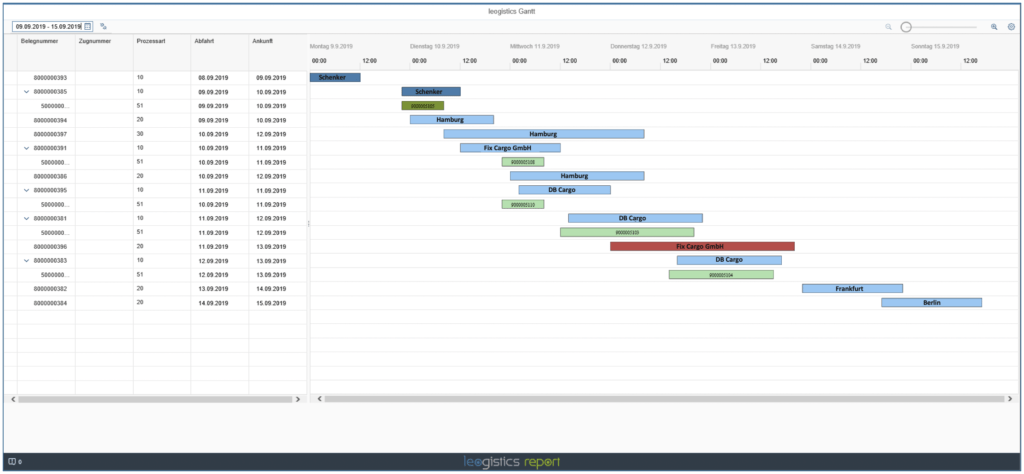

The deployment planning output is sent to the dispatcher in graphical and tabular form. GANTT charts are preferred in shift planning due to their clarity.

The planning of the circulations begins with a collaborative planning of all company locations: The locations report their respective operational wagon requirements either for the delivery of products or for the delivery of raw materials. The focus here is not on individual loading points on the plant railway, but on the overall wagon need for transport.

Rail car requirements and operating time

How long are wagons tied up in loading and subsequent transport by block trains or single wagon traffic? The scheduling system takes these type of quantity and time components into account.

The planning of the circulations begins with a collaborative planning of all company locations: The locations report their respective operational wagon requirements either for the delivery of products or for the delivery of raw materials. The focus here is not on individual loading points on the plant railway, but on the overall wagon need for transport.

Rail car requirements and operating time

How long are wagons tied up in loading and subsequent transport by block trains or single wagon traffic? The scheduling system takes these type of quantity and time components into account.

| Quantity | Time |

|---|---|

| By specifying the load weight to be shipped, the number of wagons required is determined as a function of the various wagon types available. | The required transport time is calculated from the point of departure, the destination, and the route network with consideration of various route categories. |

Integrate your planning and shipping systems

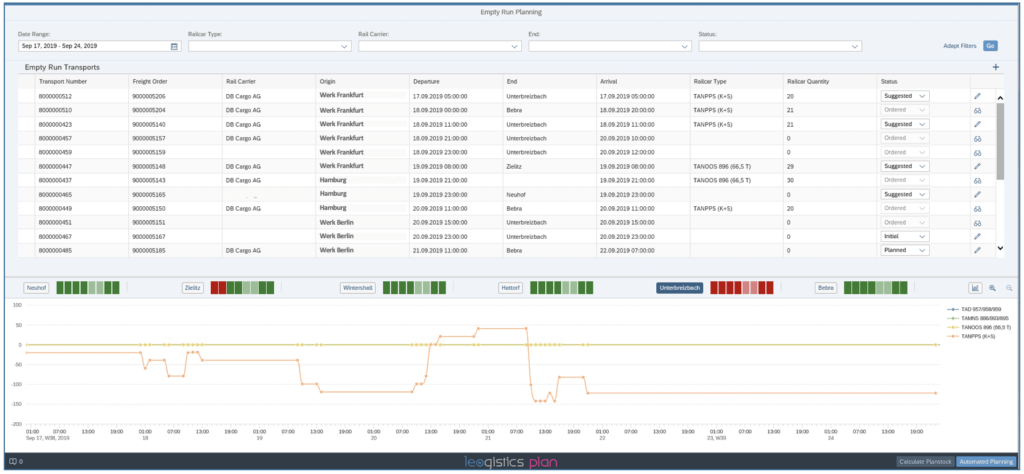

If the planning system is integrated with the shipping system, relevant process information can be exchanged automatically. Using basic data, the system first determines an optimal wagon run from the supplier location to the company, or from the company to the customer location.

But this is not where the planning ends: the system then forecasts the number of empty wagons per company location and wagon type, comparing against future wagon requirements. The goal is to calculate an optimal wagon circuit between external sinks of transports back to the internal locations.

Wagons that were used for delivery are not always returned to the original company location after unloading at the customer site. They can also be transported directly to different locations, with corresponding requirements based on the system proposal.

In the same way, the system calculates the required transfers of empty wagons between internal company locations, which can also apply to wagon turn-around planning. Forecast models in the form of planning algorithms help to identify and react to fluctuations in the period under consideration.

Making factory railways future-proof

The advantages of IT-supported planning described in this blog have been commonplace in many areas of business operations for years. Previously, the IT market lacked adequate solutions for plant and industrial railways; though, where disposition systems were offered, they were isolated solutions, without integration and planning options.

With leogistics Rail, a new, out-of-the-box solution is now available to the railway market, offering numerous benefits including:

- leogistics Rail is based on SAP technology and can therefore be integrated with all the company’s ERP, TM and EWM systems.

- Integrative planning processes for operations are a key component of the solution.

- The system supports tactical resource planning using forecasting models.

- The planning of wagon shipments by block train or single wagon takes place in the scheduling system—across the board with the shipping department.

- Through internal, collaborative planning, the company’s own fleet is used optimally, with empty wagon distributed economically.

Are you facing the same challenges with your plant railway? Have you considered future-proofing your operations? We love railways, and would be happy to offer advice based on analysis of your personal requirements!

If you have any questions about this or other topics in the blog, please contact blog@leogistics.com.

Matthias Platzer

Senior Consultant SAP Logistics