We used the quieter days over the turn of the year to look back on the past leogistics year. The larger implementations stand out, of course. 2019 was an extraordinarily successful year, especially in the plant railway.

Our solutions have risen to a new level. We were allowed to learn, sometimes had to learn the hard way and were finally able to prove that leogistics Rail is ready for the market.

Put to the acid test

The functionality of leogistics Rail was put through its paces in numerous implementation projects, and the scalability of the apps and processes was also proven:

We are live with a digital, SAP-based solution at the largest private railway hub in Europe.

This means that at only one location per day with our solution:

- 50 incoming and outgoing trains are being dispatched,

- 110 switching (shunting) orders are being created and processed,

- 2.000 single car moves are processed, and

- 1.750 units were driven on freight cars from the plant.

And that with 85 kilometers of track and 31 railway loading points.

The most important balancing act has already been tried and tested: We offer a standard solution that allows customers to map their individual processes there. Should this prove difficult, there is still the customization in the customer namespace.

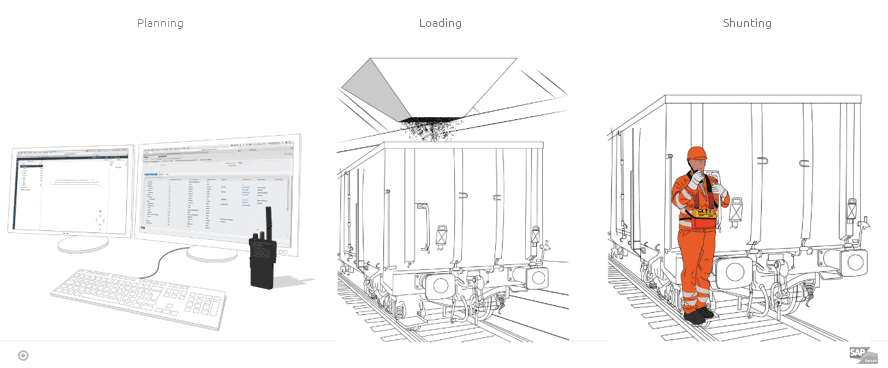

The focus is on demand-driven scheduling and processing of switching orders. The process is supported by mobile applications, such as train arrival and sequence checking on the smartphone, or a switching app on smartphone, tablet or installed device in the traction unit.

Embedding in the it landscape

Since we have been able to build up expertise in the classic supply chain execution area for many years, the integration with SAP products, which is necessary in many cases, was a possibility for us to quickly integrate into existing or created IT architectures. For example, it was just as easy to map empty car management with an interface to SAP Transportation Management as it was to use SAP tools (such as BRFplus, SAP UI5 or SAP PI/PO).

Innovation

| INTERNET OF THINGS | AUGMENTED REALITY |

|---|---|

| The simple connection of smart devices also provides a whole new perspective on process automation and security. Together with our partners we offer, for example, sensors for car detection, axle load determination as well as testing for flat spots and damaged cars. Tracking and visualization of individual cars on the track is also part of the solution. | In the field of factory railway logistics, leogistics has already been able to conduct initial tests with a head-mounted display. The correction of track stock could be carried out in the near future with the help of augmented reality. The combination of augmented reality and voice control forms the basis for the hands-free recording and documentation of logistics processes. |

Integrated processes

A key success factor of the implementations is the linking of the operational railway system with the customer’s dispatch system:

- It enables the determination of transfer requirements,

- an automated merging of cargo and freight cars, including load status change, adjustment of weight information and

- the transmission of the arrival data for the transport.

Loading point integration

If you connect your loading points with the operational railway system, they can be operated according to demand:

- Loading points report the demand for material or empty car at a specified time (for example, at predefined lead times). On the basis of this information, the factory railway can plan and schedule switching orders to serve the loading points.

- The same applies to the withdrawal of freight cars from loading points: Here, too, the reporting of requirements triggers an order to the factory railway.

Application example: finished vehicle loading

A special Use Case in leogistics Rail is the loading of finished vehicles. Here, freight cars that are moved to the loading point are loaded with finished vehicles and then pushed onto the departure track using a transfer table so that the next freight car can be loaded. The entire process is fully integrated in leogistics Rail. The loading of the freight cars is displayed (the vehicles as loads are linked to the freight car) and the repositioning of the car from the lining up to the departure track is implemented via an interface with the transfer table in leogistics Rail. Finally, the demand to move away the freight car from the loading point is handed over automatically to the factory railway dispatcher.

Extensive functional portfolio

| Step | Description |

|---|---|

| Shipping Notification | In inter-plant transport: departure of the freight at the location triggers the notification at the receiving location |

| Registration | Interface to Railway Undertakings |

| Train Sequence Check / Train Dispatch | Mobile incoming train handling (tablet, smartphone) including various correction options and damage detection process |

| Automatic Pre-disposition | Automated predisposition of destinations for cars (e.g. track, track scales, loading point) |

| Operating Plan | Demand-based operation of charging points (switch on/off) Requirement registration/-message manual or interface driven (e.g. transfer table for automobile loading) |

| Shunters Planning | Assignment of switching orders to vehicles and capacity planning for vehicles (Gantt chart) |

| Switching (Shunting) | Central or mobile installation/processing of switching orders |

| Empty Car Management | Demand- or circulation-related empty car management |

| Outbound Train | Planning, formation and handling of outgoing trains including various tests such as max. total train weight, max. total train length, maximum axle loads |

| Train Order | Interface to Railway Undertakings |

Significance of the factory railway

Due to the growing importance of factory railways as the logistical backbone of many industries and the increasing complexity in production and distribution, it is necessary to increase responsiveness and transparency through integrated, end-to-end processes.

Take the next step

We have specialised in reducing the manual effort within the bounds of a work path solution. Among other things, you can revert to the following measures:

- Integration of the large number of EDI messages provided by your railway operator to automate bookings;

- Integration of in-house systems, e.g. a loading system that provides freight information;

- Define planned movements that are generated automatically and fill the worklist;

- Utilize interface information by setting up rules how, where and when should certain and undefined cars be handled?

- Make use of barcodes and RFID to support manual processes.

What is your use case?

Are you facing similar challenges with your factory railway? We would be happy to advise you on the analysis of your personal needs!

If you have any questions about this or other topics in the blog, please contact blog@leogistics.com.

Marco Mohr

Arvid Kauffeld

Consultants SAP Logistics