The advantages of an integrated scheduling system

Digitalization has long since established itself in all areas of business: IT-based processes have been the norm in management, human resources, and accounting for decades. In production and logistics, creating value is hard to imagine without automation, a carefully integrated supply chain, and digitally driven processes.

Still today, digitalization has not found its way into all logistics areas. For instance, one area that seems to successfully defends itself from any kind of IT support—the factory railway process.

Regardless of whether the station operates a short connecting track, or a widely branched in-plant rail network, except for a few PCs in the office for the registration of wagon stocks and statistics, there is rarely any additional equipment for the shunting operation.

The need for systematic operation planning

While on factory premises, trucks are routed via route-optimized, time-window controlled loading gates based on dispatch times. Compare this with common rail processes, where shunters communicate with radios for inbound wagon deliveries, and you might begin to wonder how rail has “escaped” IT for so long. Is this really the future of the first and last mile of rail transport?

With an integrated dispatching system, the factory railway process can be rapidly digitized. A simple implementation project illustrates the difference between an outdated, manual-based process, and an IT-based, future-proof process landscape.

What characterizes an automated railway?

The employees on the track (shunters, shunting managers) receive mobile devices on which they can see their current tasks and the current operating status. Office employees (shunting dispatchers) in turn can participate in the current operating situation via desktop applications. The goal is to design the communication and work assignment between dispatchers, loading points and maneuvering staff as a digital workflow.

Printed work instructions, on which manual processing is documented, could now be a thing of the past. Let’s dive into an example process together:

Train Reception

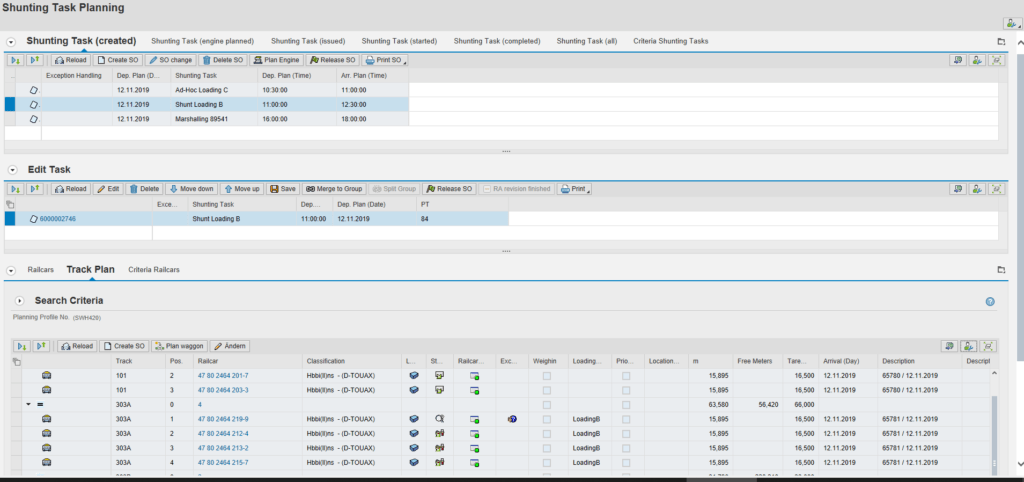

The current wagon arrivals can be viewed in advance and the dispatching of employees by the shunting dispatcher can take place via a connection of train reservations of the railway undertaking (RU) to the integrated scheduling system. This assigns personnel and traction vehicles per order, whereby a clear picture of the current and short-term utilization in the form of a GANTT chart can be displayed at any time.

After arrival, the shunter on the track sees his work orders for the newly arrived train on the mobile device (e.g. uncoupling train locomotive, securing the remaining wagon set). Of course, there are also target track, scheduled start time, and wagon details on the display. In this way, walking to an office to pick up an order is completely eliminated. In addition, the shunting device documents the processing directly on the mobile device with feedback in the system – removing the need for radio contact with the shunting dispatcher. After the operational ranking check of the wagon train and documentation of any deviations from the previous report, everything is ready for train dismantling.

Train Routing

The loading points have access to the planned train inputs via desktop applications and can order the wagons for unloading long before actual train arrival – based on wagon number, consignor, or load. This forward-looking order optimally manages the shunting personnel—any peak loads can be smoothed in advance.

The train decomposition takes place by the shunter or the shunting conductor. The wagon orders are used as the basis for the division of the train set—car groups are formed by the shunters directly in the mobile app. Alternatively, office employees can generate a proposal for car grouping on his desktop application from the system and transmit it to the maneuvering staff.

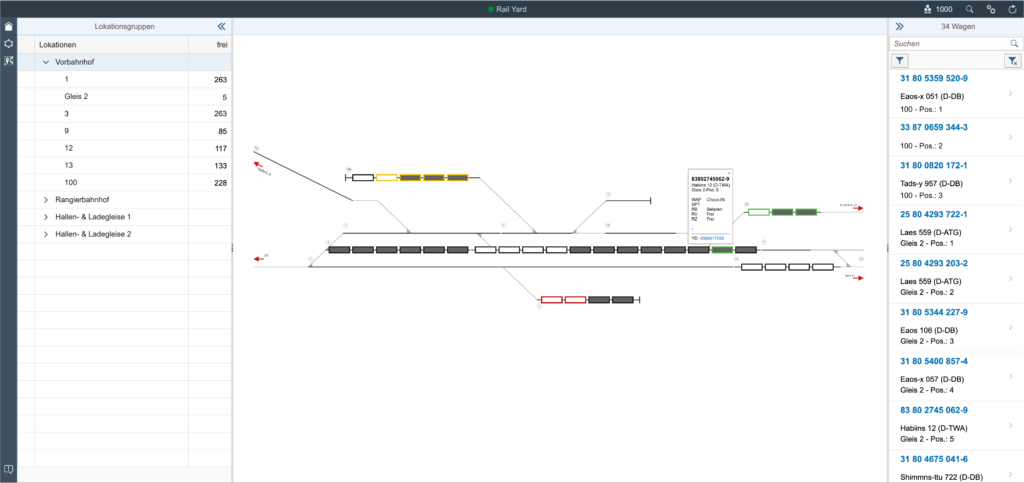

All shunting operations are documented in the system. This has the advantage that a current view of the track occupancy is available at all times. All employees at the site have access to a visual track record—effectively ending the days when employees manually maintained track lists or kept wagon stocks in a spreadsheet.

Siding operation

Planned shunting trips from entrance groups to the loading track are clearly displayed in the mobile app. The marshalling staff will see the wagon or wagon group, source track and rank in the track, destination track and position, as well as the scheduled start time. When the trip starts, the processing starts and the actual start time is reported back to the system. Upon reaching the destination track and on delivery of the wagons, the order is confirmed, and actual end-time documented. On one hand, the electronic track diagram is kept up-to-date, on the other hand, all operational data is stored in the system. The latter enables subsequent reporting—more on that in the following section.

Ideally, the system not only supports planned shunting trips. The shunting manager can add and document unplanned shunting movements in the application at any time.

Empty wagons stored at the location can be viewed by all involved parties in one central application. Loading points can request wagons for loading using wagon number or wagon type. The system automatically reports wagons with a long vacancy time to the shunting team and recommends a return to the RU to optimize wagon hire costs. In this case, a set of rules can be stored in the system. For example, for special wagons or for wagons restricted on the market, alternative recommended return times are taken into account.

Train Composition

In the scheduling system regular train departures are recorded in timetables. Special trains can easily be added ad-hoc. The shunting dispatcher plans the shipments to the respective departure times. The wagon is posted directly in the system, which communicates with the booking platform of the operating RU.

The planning of wagons on exit trains results in individual, planned shunting movements. After assigning the orders to locomotive and shunting teams, the shunting dispatcher releases the orders, which are then transferred to the personal worklist on mobile devices in the track area. Similar to the shunting orders in train breakdown and loading station operations, the employee on the track receives detailed information on the wagon movements and documents the start and end times. In addition, unplanned events can be logged for all maneuvering operations. If it’s not possible to move the entire group of wagons at once, or if the destination track is occupied in the meantime, these deviations can be reported to the system. The MRP system responds accordingly and automatically generates follow-up orders without the need for further action by an employee.

Train departure

Through integration with the operating RU, current train departures can be reported to the system. If there is no integration, the employees on the track can manually record the departure of the train in the system. Both methods keep the track layout and wagon inventory up-to-date.

Added benefits: reporting and statistics

As can already be seen in the example process, the system logs a complete image of the execution data in the background, without the need for additional manual entries. The data can be freely combined with and processed alongside other information. Both quantitative evaluations (number of carriages in the entrance/exit, number of trolleys, etc.) as well as time evaluations (average duration of shunting, duration of incoming service, etc.) are possible. Automated reporting can be enabled and applied to any period of time.

Digitalization made easy with leogistics rail

Converting a traditional, manually operated railway, to a fully integrated, IT supported operation can happen in as little as two months with the implementation of our dispatching system leogistics Rail, an out-of-the-box solution for rail operations.

leogistics Rail offers all the advantages of the digital division of labor described in this blog post with the flexibility for additional innovative components based on our customer needs. In contrast to conventional scheduling systems in the railway environment, leogistics Rail is based on SAP technology, enabling added benefit with integration to ERP, TM, and EWM.

Would you like to learn more about implementing a modern, user friendly railway process? We would be happy to benchmark and offer guidance on your specific requirements. Introducing a digital rail strategy has never been this easy—see how you can benefit today.

If you have questions about these or other topics in the blog, please contact blog@leogistics.com.

Matthias Platzer

Senior Consultant SAP Logistics