Internet of Things with SAP EWM

Digitalization in intralogistics isn’t just a vision of the future—it’s happening now. We are in the middle of the fourth stage of industrialization; topics like IOT, blockchain, artificial intelligence, smart robots, and swarm intelligence have arrived on the warehouse logistics scene with big potential to increase flexibility and process efficiency.

There are a multitude of possibilities for using IOT components—making it a difficult topic for overviews. Therefore in this article, we’ll outline select areas of digitalization in warehouse logistics, and share exciting examples of integration with SAP EWM, aiming to provide compelling arguments for the digitalization of warehouse processes.

Logistics as a value driver

Previously underestimated as a value-adding factor, today’s logistics processes are widely recognized as value drivers – both in growth and increased efficiency.

From sensors with automatic identification capabilities—to autonomous transport and automated warehouses—technology is enabling unprecedented, and extensive self-control.

Smart Logistics

The Smart Logistics approach goes one step further: maximum transparency of the logistics chain enables all parties involved to react directly, and in a coordinated manner to process deviations. It’s important not to equate the digitalization of (intra) logistics processes with complete automation.

On the contrary, digitalization is about networking machines, people, and setting up self-guided “control loops”. These control loops consist of sensors, people, and operating machines, with processing and feedback of real-time process data.

Advantages of collaboration and real-time data exchange

Cloud-based services for real-time traffic data and dynamic route planning, for example, can make picking and provisioning processes more cost-effective. Intelligent technologies can be used to remotely perform and predict maintenance more accurately. Inventory counting can also be optimized.

The use of drones, or an app that supports cycle counting with image recognition can drastically reduce the duration of taking a physical inventory. If manual counting by hand takes 2 to 3 minutes per item, a photo can digitally deliver the count within seconds. In a warehouse with thousands of items, the entire inventory cycle can be dramatically shortened, enabling additional productivity of resources.

Benefits through automation

In addition, automated guided vehicle systems (AGVs) will become increasingly important in the course of the digitalization of warehouse processes. The rapid development of smart sensor technology plays a major role in the development of AGVs. The built-in intelligent sensor technology enables sudden obstacles to be detected quickly and accurately, helping to avoid crashes while waiting for the obstacle to be cleared. The goods-to-man process can be completely redefined. In the future, milk runs can be mapped between the warehouse and workstations via AGV. In connection with wearables, such as a Smartwatch or Smart Glasses, the employee can display the arrival and loading of transports, and if necessary, prepare exchange containers or finished components for handover.

S/4HANA and sSAP EWM as the basis for digitalization

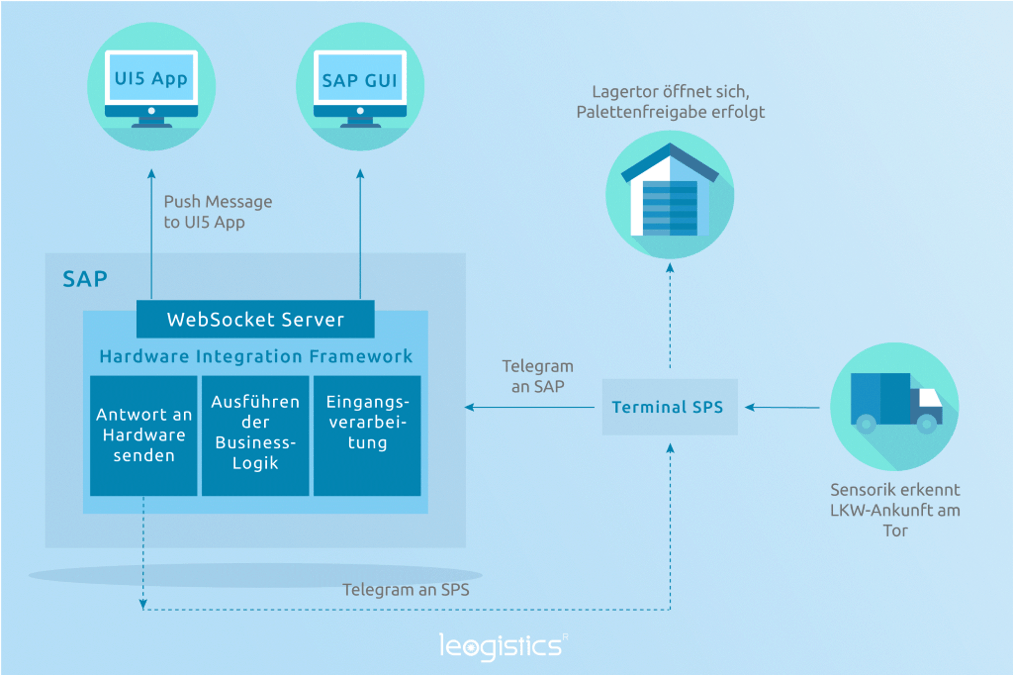

Increased data volume – due to the availability of live data and the associated increase in processing speed – can be intercepted by S4/HANA InMemory technology. In order to integrate data to control processes, and for automation of subsequent steps in digitalization projects, we have developed a standard interface.

How does integration with SAP EWM work?

Our specially developed interface currently supports protocol types such as HTTP(S), WebSocket, and TCP/IP. The data formats used are JSON, telegram strings, and XML. Additional data formats can easily be integrated.

Depending on the application or IoT component, business logic is programmed in SAP EWM. There is also the ability to push incoming and outgoing messages directly to a web-based user interface—without additional development. In this way, a wide variety of terminal devices can be utilized. Here are some example use cases:

- Capturing truck license plates and trailer numbers

- Identifying parking slot vacancies in loading/unloading areas

- Monitoring compliance of “cold chain” logistics, like fresh produce.

With SAP EWM and the right IoT components, there is a great variety of automation options including:

- High-speed sorters

- Rack servicing equipment with transfers to the next aisle

- Picking robot with pallet wrapper

- Automated guided vehicle systems

There are two important questions you should make sure to answer before beginning the integration. First, who owns each function? Also, what is the depth of integration with the hardware?

Application examples

At our in-house lab (the leolab), we constantly research and develop topics that provide added value in the logistics environment.

Here are a few examples of recent innovations:

- SAP EWM reorganization tool based on a sophisticated algorithm

- Integrated use of chatbots and voice control

- An inventory counting app based on AI and Machine Learning

Inventory assistance through machine learning

Based on neural networks, we’ve developed an app that can count the number of pipes, trunks, or any “learned” objects by cross-section and shape. With this app, we can eliminate the traditional, time-consuming, and error-prone inventory counting process.

Work facilitation through voice control

The standard integration of Alexa voice commands with SAP EWM is made available by process codes. These can easily be extended with EWM “Alexa skills”. With predefined dialogs and the ability to train Alexa, enabling freehand management of the warehouse is becoming more and more a reality.

Chatbots and user-centered screen layouts can be used to shorten training phases for employees, carry out training courses individually, or to explain system innovations, guiding your employees purposefully through the process.

By loading the video, you are agree to YouTube privacy policy

Learn more

Are you ready to plan the next steps in digitalizing your warehouse?

The digitalization of the logistics chain remains a decisive factor for cost-optimized logistics processing. Most recent innovations in the space revolve around process optimization through use of smart hardware components, ever-evolving algorithms, and their direct integration with SAP EWM.

Which process steps will you optimize in the near future? Are you actively looking for possible application scenarios? Let leogistics know how we can help!

If you have any questions about this or other topics on the blog, please contact blog@leogistics.com.

Florian Schorcht

Henry Böhland

Consultants SAP EWM