How digitization is gaining ground in the port logisitics sector

Maritime transport has always been characterized by difficulties in the planning and reliability of information. Weather conditions and environmental influences have a direct impact resource requirements and planned departure and arrival times of ships. Even slight delays can cause a domino effect. In the following, we explain to what extent, automation and digitization can have an impact on performance and customer experience in the port logistics environment.

This week we will focus on how to become a digital port. Next week, we’ll explore automation opportunities in the port environment.

Market changes in the maritime logistics environment

When we exchange information with our network partners, certain developments in port logistics become apparent again and again:

- The consolidation and formation of alliances in the area of shipping lines has led to a shift in power, forcing port and terminal operators to cooperate and enter into partnerships.

- In recent years, there has been an enormous demand for container capacity on ships, which has been met by newly ordered and larger ships. Now that supply and demand are converging again, it can be assumed that after a phase of extreme growth there will be room for necessary—and perhaps overdue—digitization and automation processes.

- Impending penal duties and the expected slump in the global economy are increasing the pressure on shipowners and port operators, as margins are at risk and pending investments in unloading and loading equipment as well as the IT infrastructure must be covered.

- As in other branches of industry, maritime logistics also faces the trend of increased demand for information from network partners: Where are my goods, when do they arrive, what is the turnaround time of a ship? Real-time information is the key to success, and at the same time the unique selling proposition compared to the competition.

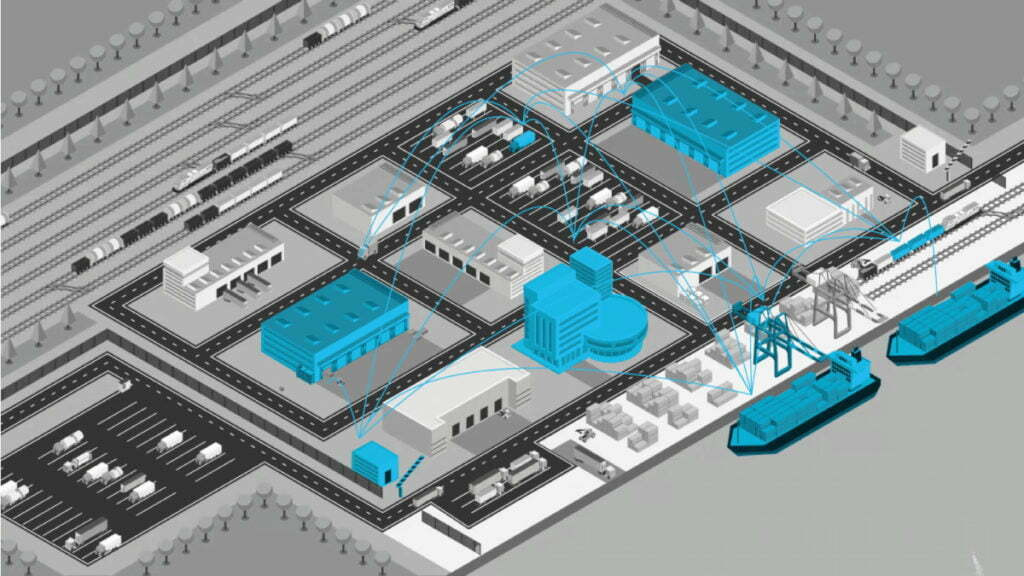

Our vision of the digital port

A few days before the arrival of a ship, the planning has been completed: Sufficient resources are blocked to complete ship activities within the planned turnaround time. The 3-week forecast provides us with a complete picture of the work volume. Bookings were made by agents via a partner portal and on the basis of vessel schedules.

We can also already make a statement about the freight to be handled, as loading and unloading lists have been sent to us electronically. Short-term changes can be taken into account, as information for delivering and collecting trucks is transmitted in a uniform format. We also have detailed information about incoming and outgoing trains via the interface of the railway company.

We report progress both internally and to our partners during the discharge and loading process, which is recorded in real-time using mobile devices. In this way, the flow of goods into the warehouse or onto a further mode of transport can be adapted to current conditions. The means of transport for the preliminary and main legs were notified in advance and are now recorded electronically on entry and exit.

Billing takes place immediately afterwards, as we have direct electronic access to information on services performed and exact quantities. Customers rave about the customer experience because cargo-related information is now available in the supply chain.

On way to the networking port - a roadmap

In a Whitepaper, the British Ports Association and the Port of Rotterdam have drawn up a four-stage milestone plan which outlines the roadmap for the digitization and networking of a port. The goal is competitiveness and the acquisition of new customers.

-

Digitization of the process participants in the port

The recommendation: Start digitizing the processes of the individual participants on a small scale. -

Creating integrated systems in a port community

Data obtained via a central platform enables reliable, efficient and paperless information flows. -

Integrating the logistics chain with the hinterland

Looking outside the box: In addition to those involved in the process in the port (e.g. port authority, terminal operators, shipping lines, agents), hinterland terminals, container depots and carriers are now also integrated into the digital exchange of information for better planning. -

Connected ports in the global logistics chain

The last step is communication between the individual ports, which in turn are linked to their hinterland. The result is an end-to-end logistics chain that optimizes the use of different means of transport.

This step-by-step approach represents an excellent basis for the creation of your individual roadmap. Below you will read how information can be captured and shared, and what immediate benefits it can bring you. The focus is on the first steps of the whitepaper.

Where do i start digitizing my processes?

It is important to determine how detailed and up-to-date the information to be collected is, in order to digitize processes. This defines the number of process steps to be digitally captured.

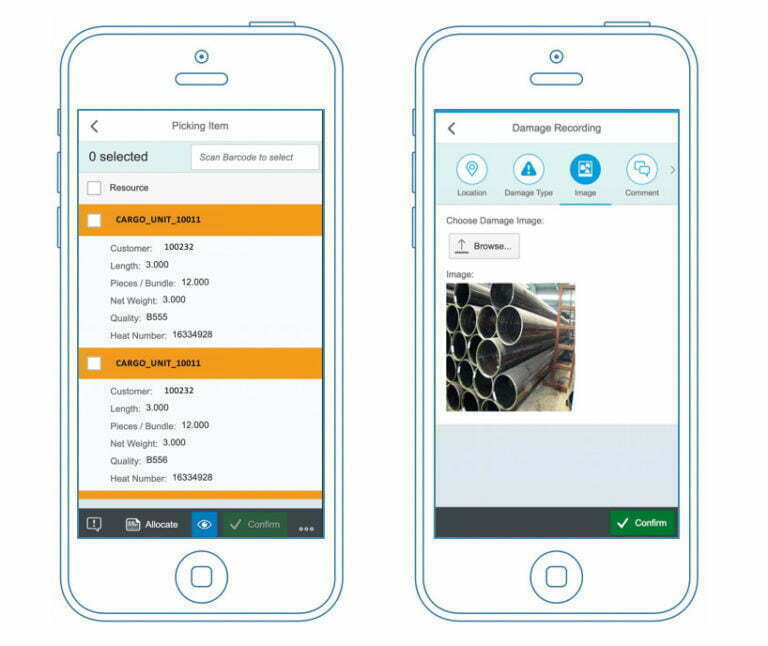

For general cargo handling, mobile devices with WiFi and 4G are in use, which allow real-time tracking by scanning barcodes on the loading units. They access lists live and confirm cargo movements at ID level. The progress of the trans-shipment work and productivity can thus be easily determined and made visible for customers or internal purposes.

The smooth flow of information within one’s own IT architecture is an important success factor: If the order for the ship’s arrival is available electronically for planning and handling, as well as bill of lading and manifest information, then this continuous document flow allows detailed monitoring and reporting for all parties involved. Deviations from the plan are then identified at an early stage and countermeasures can be initiated.

How can i integrate with my network partners and create collaborative systems?

The information gained is an important asset for logistics service providers. It is often difficult to ensure the flow of information in the port between the individual persons involved and IT systems.

The success of selected digitization measures can only be achieved if supply chain processes are sufficiently interlinked.

Information flows across software and company boundaries reveal optimization potential that can be exploited through process interlinking.

One example is the handling of trucks in the terminal:

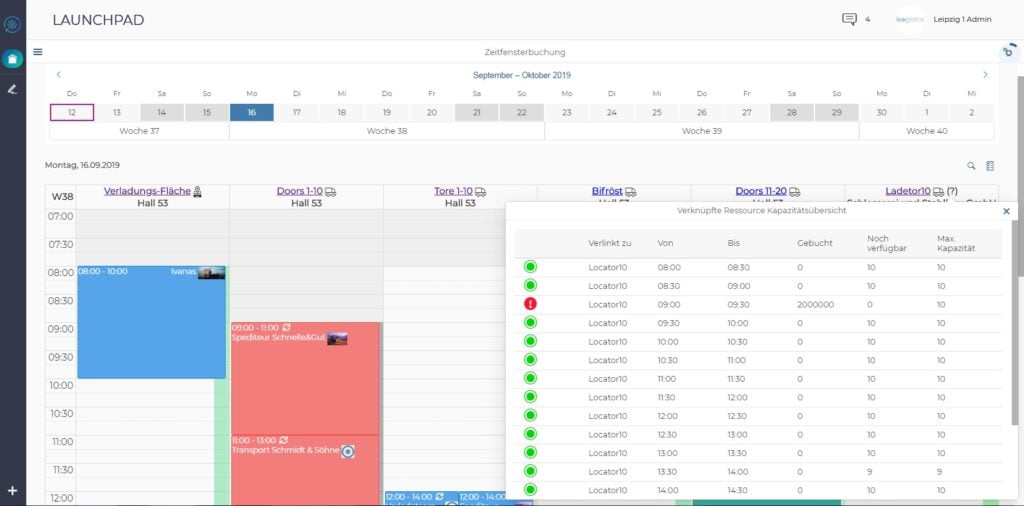

Notification of the truck with information on driver and means of transport data, a time slot and the last loads lead to shorter processing times and increase process reliability.

How can i use existing capacities more efficiently with the newly acquired information?

Digital berth planning and traffic control are a must-have in order to survive as a port with international competition. They help to optimize productivity, since terminal and hinterland logistics can inform themselves in advance about the time of the vessel´s arrival and plan accordingly.

Shifts in the process can be made visible and accessible in real-time. Capacities that become available can be rescheduled and possible capacity bottlenecks can be detected at an early stage. Storage areas can also be used more efficiently if ship arrivals and loading and unloading volumes are processed in a forecasting tool. It is important to make this capacity-related information available online and share it with supply chain partners. With this type of information, customers and partners can book free time slots for vessel handling and lock times, even storage space—at short notice—in order to increase productivity. Each of these improvements make a service provider more and more attractive from a customer’s point of view.

Concrete measures for digitization

Are you operating a terminal or a port and would like support in implementing concrete digitization measures? We would be happy to offer advice, and to help uncover potential within the scope of a digitization workshop:

- Which network partners (customers, service providers, partners) can be embedded in existing or new processes in order to optimize the flow of information in both directions?

- How can you position yourself as part of a collaborative supply chain in which electronic status messages are exchanged to make delays, damage reports or general transport data available?

- Involve your customers and partners in the digitization process! We would be happy to conduct a survey with you to find out what data a partner can provide and what he expects from you. This will enable you to improve your relationships and position yourself better for the future.

If you have any questions about this or other topics in the blog, please contact blog@leogistics.com.

Jan-Philipp Horstmann

Senior Consultant SAP Logistics