What's new in the SAP S/4HANA 2020 FPS01 release? (part 2/2)

On February 24, 2021, SAP SE presented the new S/4HANA 2020 FPS01 release to the public. In our article “SAP S/4HANA 2020 FPS01: SAP TM and EWM improve Interface Communication” we have already presented the advantages and innovations for the Transportation Management area.

However, FPS01 not only offers new possibilities for TM, but also on the other side of the warehouse gates we get a slew of interesting enhancements for EWM. Thus, SAP addresses many important issues that we have stumbled across in our daily work so far. We would like to explain some of them to you in the following.

Advanced Shipping and Receiving in SAP EWM

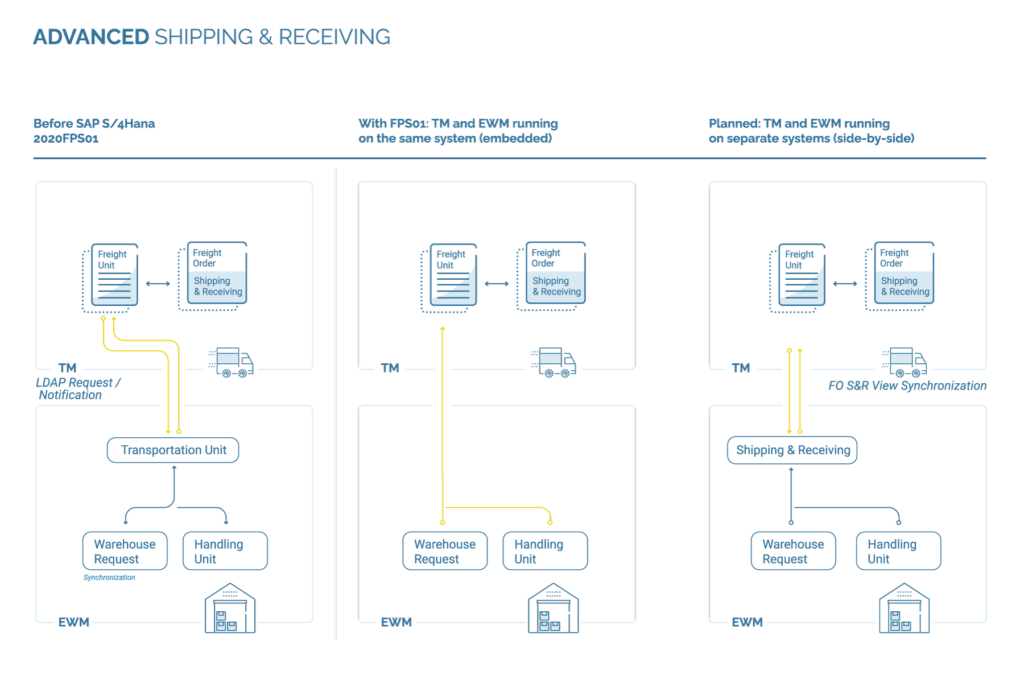

One of the most exciting new features of the release is Advanced Shipping and Receiving (ASR). We have already described the facilitated collaboration through the improved data synchronization between SAP TM and SAP EWM. This eliminates the need to replicate freight orders as transport units. Instead, we can now work directly on the TM freight order (and thus have access to Advanced Shipping and Receiving). In the first step, however, this is only possible on an “embedded” system, which SAP sells under the slogan “no data replication necessary”. We are looking forward to 2022, when this object sharing is also to run on standalone systems.

In truck handling, the use of the Freight Order has the effect that a truck can now both unload and load at a loading point. In addition, the Freight Order can now also contain an EWM- and at the same time an MM-IM-managed storage location, e.g. in order to supply production sites according to demand. Both storage locations share a loading point in the scenario.

Warehouse logisticians can perform the actual booking activities via new or adapted user interfaces. SAP promises not only suitable GUI and Fiori transactions, e.g. to assign a gate or set the loading status, but also new RF transactions for the still popular MDE devices. By editing the freight orders in the warehouse, these objects are also enhanced with EWM-specific fields to match the tasks of the warehouse staff. All relevant changes can also be viewed directly in TM by editing on the freight order.

Not quite as prominent are the constraints that are not covered by FPS01. These include the mapping of stock at TU level, a loading of a freight order with an ad hoc freight unit allocation, and a load planning before packing and staging of HUs. In addition, EWM Yard Management is limited to “check-in” and “arrival at gate” activities. If you want to bypass such limitations and manage your yard in a future-proof way – feel free to contact us.

Many improvements of EWM also in combination with ERP and QM

FPS01 2020 helps EWM to communicate not only with TM, but also with ERP and QM. SAP seems to have responded to many wishes of its customers, which we also know from our project business.

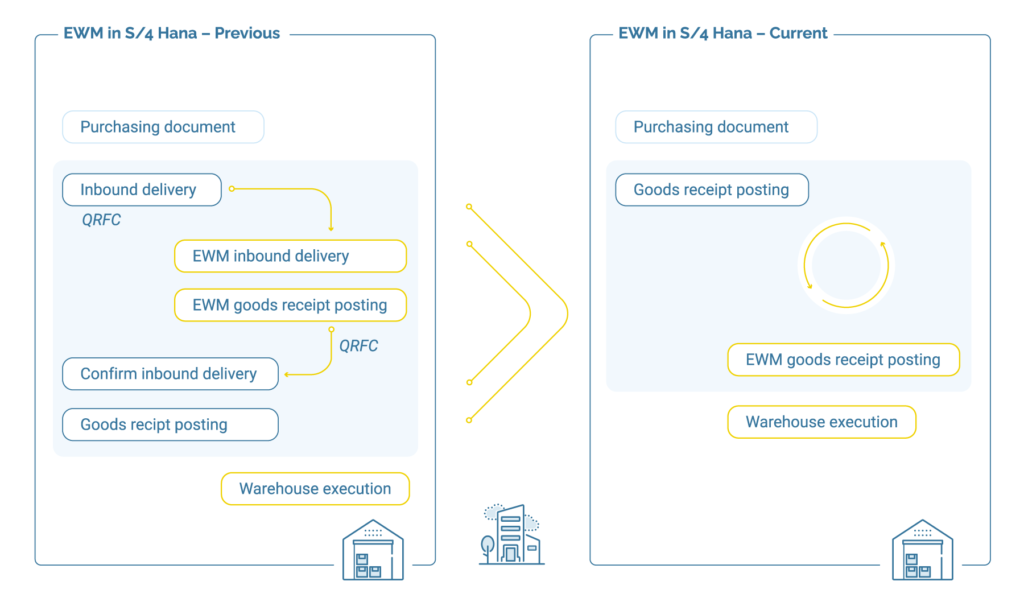

In the future, the standard transaction MIGO will synchronously post a goods receipt in EWM for an external procurement. If this posting runs into an error in EWM, this no longer appears in the queue, but is displayed to the employee directly in MIGO as an error message. Another clever feature is the possibility to mix the goods receipt in an MM-IM storage location with an EWM storage location in one posting.

Logistics Execution users can enjoy the fact that direct synchronization updates the exact delivery quantities from EWM. In this way, the end users already see the corresponding change in the system when the quantity is adjusted in EWM – and not, as it was previously the case, only when the goods receipt is posted.

For Quality Management on decentralized EWM systems, there is now a feature that previously only ran on embedded systems: “Scrap to Cost Center” and “Sample consumption” can now be defined as follow-up actions for corresponding usage decisions.

The following enhancements are intended to facilitate batch management in decentralized EWM and improve data consistency between ERP and EWM: First, newly created and changed batch masters are distributed directly via the ALE framework, without the use of change pointers. SAP promises that this means that existing solutions do not have to be adapted. The trigger for the distribution is the change on the database itself and not the transaction or job in which the batch is processed.

Integrative batch processing will be further enhanced: In SAP EWM, the MSC1N and MSC2N transactions are provided for creating and changing batch masters. Finally, warehouse employees can add a new batch during inventory that was not previously available in the system – of course with synchronization to the ERP batch master.

Reduced costs for new launches thanks to Fiori App

The next innovation helps in particular to reduce the costs of new implementations, both embedded and decentralized SAP EWM, by reducing development effort: Additional master data fields can be added in the material master on a customer-specific basis. For this purpose, a Fiori app is provided in which the fields can be added to the storage type and/or warehouse data. From our point of view, this is rather a small point, but it is a practical help for most customer projects.

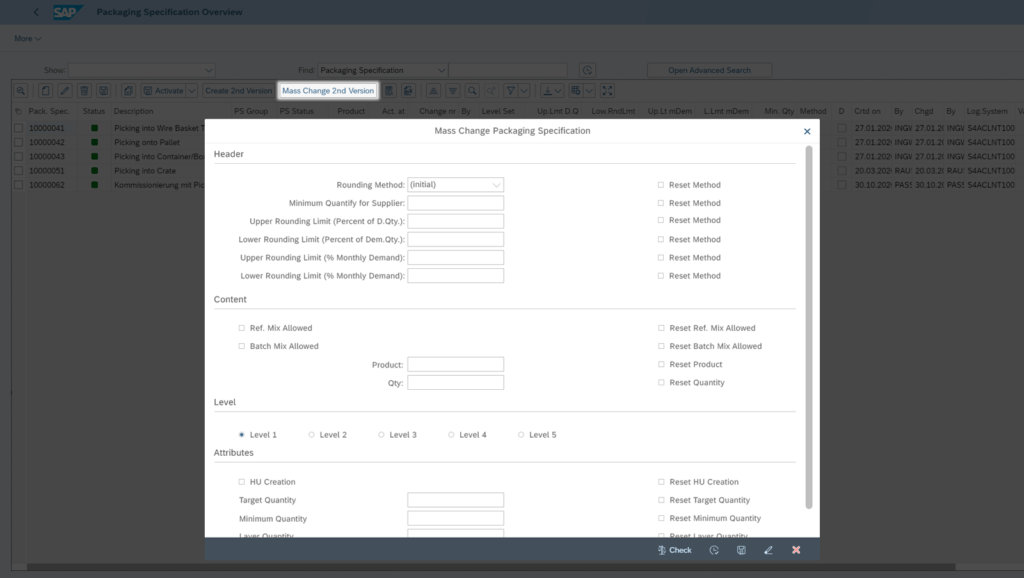

Every person who has ever dealt with pack specifications will also be happy about the following point: With the new feature pack, bulk changes can finally be made to the PackSpecs. The grueling repetitions of hundreds of identical entries will hopefully be a thing of the past.

In summary, we see the presented features of SAP S/4HANA 2020 FPS01 as useful and practical enhancements for the SAP EWM system. Both new implementations, subsequent process adaptations as well as day-to-day business will benefit.

We are here for you

In conclusion, it can be said that Advanced Shipping and Receiving in particular will have the greatest impact on future projects. SAP is thus passing an important milestone in the development and merging of transport and warehouse processes and is taking the next step towards an integrated supply chain. It’s worth taking a closer look at what’s new in S/4HANA 2020 FPS01.

If you too are thinking of making the switch, let us know: SAP is still looking for early adopters for Advanced Shipping and Receiving. In these programs, SAP offers a direct line to the developers of the applications. We would be happy to help you participate. We can also support you in making your operational processes more efficient, transparent and cost-saving, thus improving your supply chains. Have we piqued your interest? Then please feel free to contact us.

If you have any questions about this or other topics in the blog, please contact blog@leogistics.com.

Frank Meier

Jens Arndt

Consultants SAP Logistics