How to optimize the transport of planning of waggons in SAP TM almost automatically

Having already dealt intensively with the railcar as the linchpin in the last article in order to illustrate the logistical process of the railway, we now turn our attention to planning.

In the following, we look at the planning of railcars in SAP TM as central resources.

The planning process

Via the logistics modules SAP ERP, S/4HANA or another upstream system, you can transfer sales orders, purchase orders and deliveries to SAP TM via XML. In the case of a side-by-side deployment order or delivery-based transportation requirements are created during the transfer, which mirror the source system documents in SAP TM. If SAP TM is used integrated in a complete S/4HANA system, the system generates freight units directly. To create the freight units, the freight unit building rule is triggered, and freight units or railcar units are created automatically.

The direct generation of railcar units is useful if the split quantities in the freight unit building rule have already been adjusted to complete railcar and thus a division into freight units becomes obsolete. If freight units are created from the freight unit building rule, additional planning of freight units on railcar units must be carried out (multi-level planning in SAP TM). You can find more information about planning rail processes in our blog.

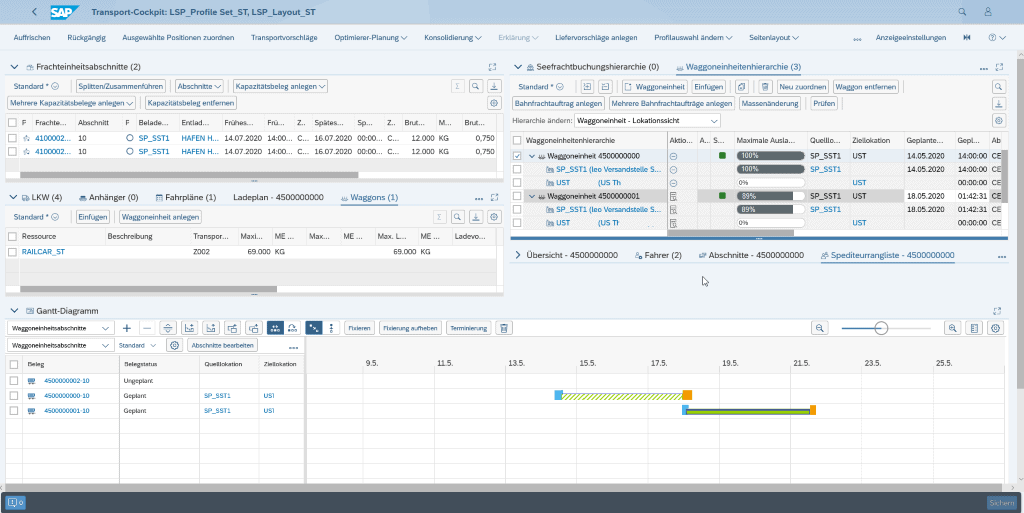

Keep anything in sight with the transportation cockpit

The planning and optimization process is handled in SAP TM using the Transportation Cockpit. Here the freight or railcar units can be planned for freight orders. A freight order is also assigned to a traction vehicle (for traction) and, if necessary, an underlying schedule.

On what can you resort to in the planning process?

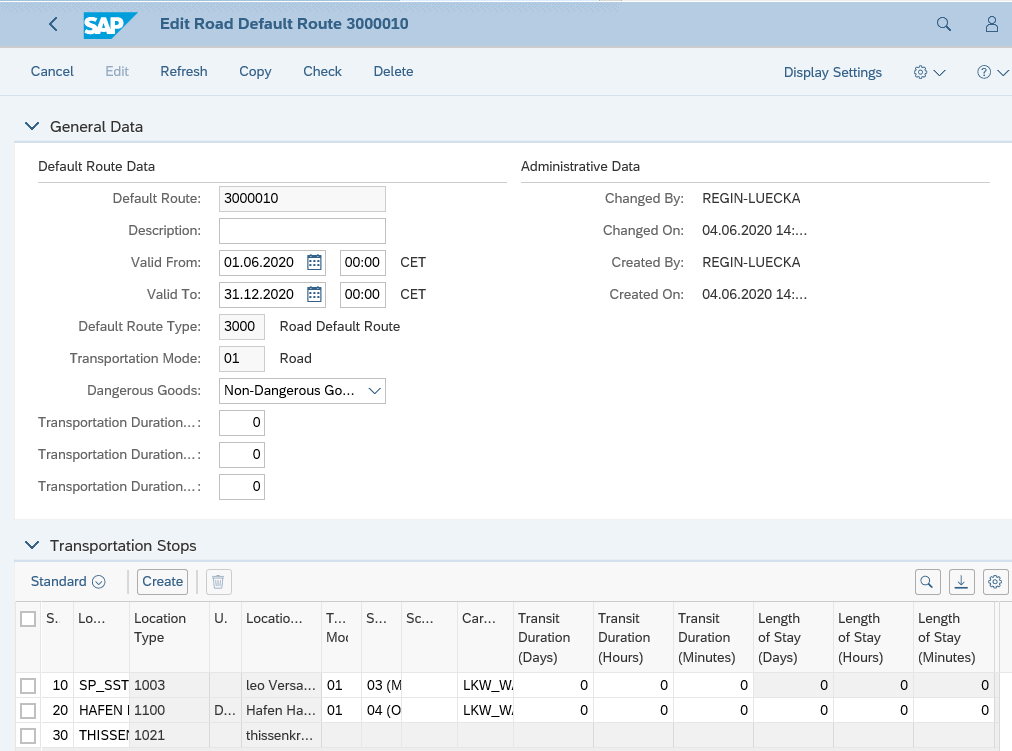

- When planning a shipment, so-called default routes can already be taken into account in the freight unit building rule to split the freight units into stages. Default routes are part of the transportation network and are used in SAP TM to define a sequence of marshalling and transshipment points and thus of shipment stages in the transportation network. For each default route, for example, the means of transport, railroad company, and schedule can be specified for each stage of the transportation network. The system therefore considers default routes as a route for a shipment between two locations.

- SAP TM also offers the possibility to carry out fully or semi-automatic planning via the VSR optimizer (Vehicle Scheduling & Routing) and directly assign the relevant railway undertaking (RU).

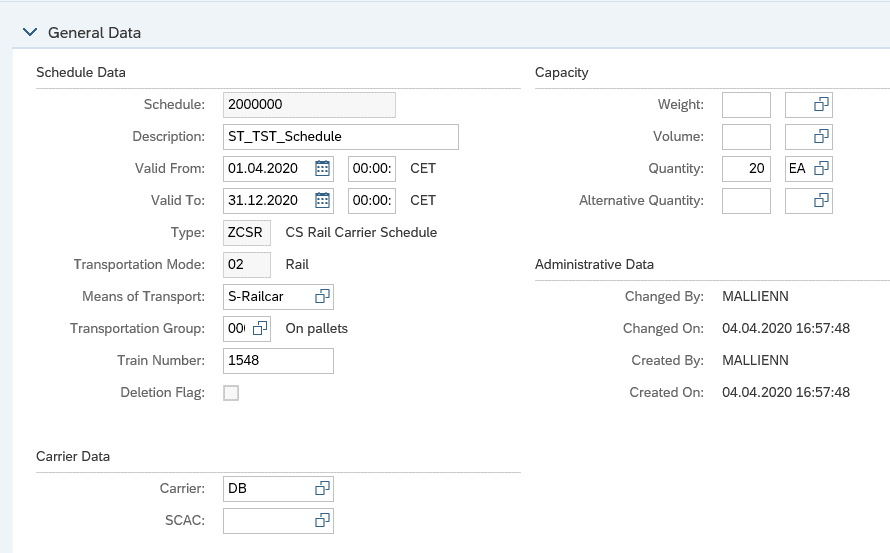

- Using VSR planning, a default route and schedule can be used to schedule the freight unit sections to freight orders/trains. In schedules, the sequence of stops, such as stations or gateways, can be defined that are valid for a certain traffic period. Schedules can be assigned directly to an executing RU. By specifying departure rules, departures can be generated automatically on a daily basis; this reflects the traffic days of the transport connections. The system calculates the arrival and departure times at each individual stop of a train or transport run (systemic: arrival sequence) and takes into account the transport duration for each stop. In contrast to other schedule types in SAP TM, train schedules can be given the train number and a capacity.

Use of the optimizer

When planning via the VSR optimizer, the loading time windows at the source location (source loading point) as well as the delivery dates at the customer (possible arrival times at the receiving railway station) can be taken into account. This is made possible by using the calendar and handling resources of the dispatching and receiving stations as well as the scheduling settings of the planning profile.

| Calendar resource | Calendar resources can determine the operating times of locations by defining shifts and downtimes and assigning the resource to a location. This reflects the opening hours of the participating stations. |

| Handling resource | Handling resources determines the handling capacity with which goods can be loaded or unloaded using a system or device (e.g. gates or reach stackers). This reflects which shunting teams are in operation with which locomotives at each railway station. |

| Planning profile | In the scheduling settings in the planning profile, you can define the loading duration and coupling time for certain locations and means of transport in order to optimize the delivery time and avoid delay costs. This reflects the train formation and train splitting times at the locations. |

Capacity utilization planning

Another way of reducing costs is to ensure high capacity utilization of trains and railcar. In SAP TM, you can map this by means of execution blocks on the freight orders, which are only removed systemically when a certain capacity utilization of the train (in this case the freight order) is reached. In this way, planned train services can be rescheduled to other schedule situations at short notice.

Event-based status reports

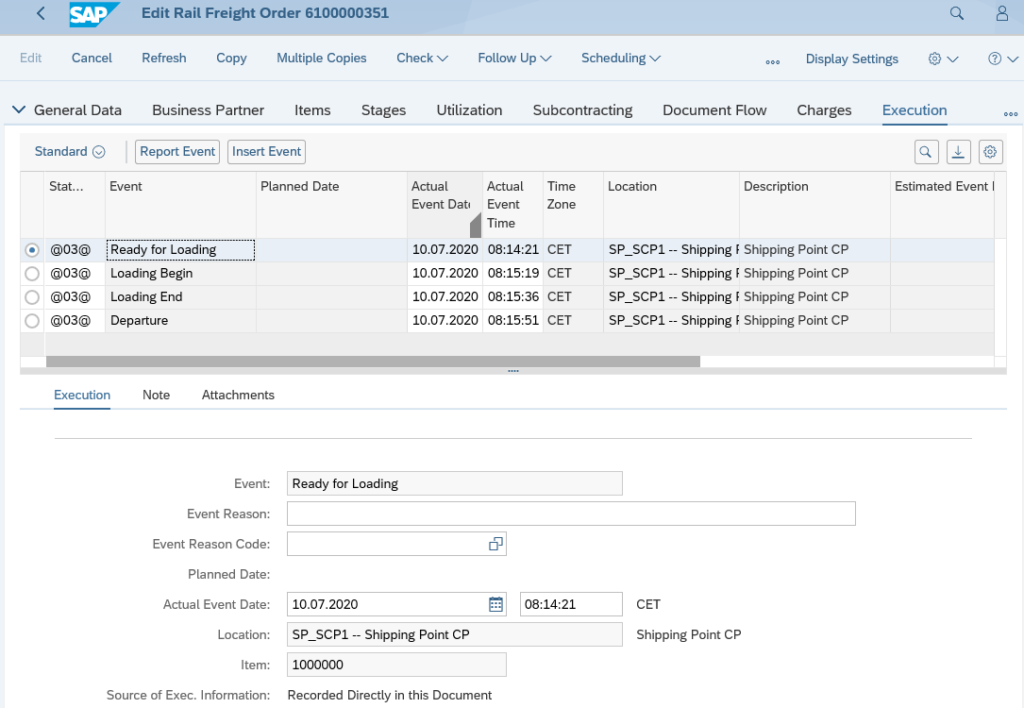

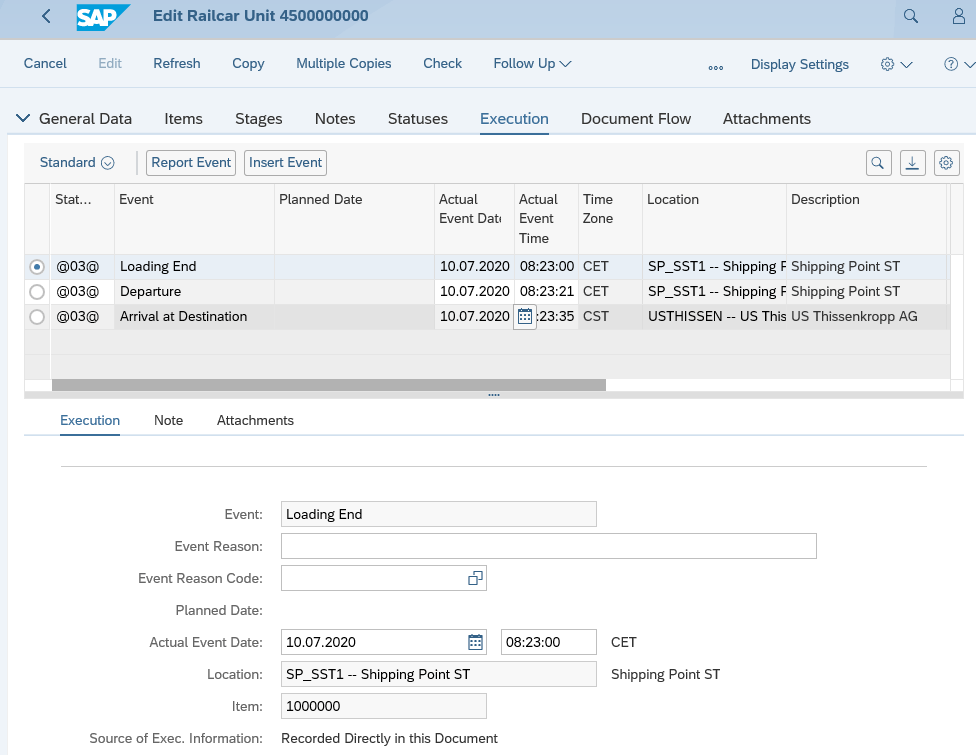

Using an interface to the preloading or loading system on the one hand, and manually on the other hand, events can be set in SAP TM per train or railcar and thus the following statuses can be reported:

- the provision of the railcars at the loading point,

- the start of loading,

- the complete loading of a railcar,

- a notification of the start of the transport (departure of the train at the station of dispatch) and

- the arrival of the train at the receiving station or the delivery of the railcars at the receiving loading station.

Consolidation of cargo

If one or more freight units are to be allocated to a railcar unit before this railcar unit is assigned to a train, load consolidation must be performed. Here the freight units are planned for a railcar unit either taking into account the volume of the railcar unit or using loading space planning. In both variants, incompatibilities can be used to find the correct railcar type for a freight unit.

For example:

- Load a certain material only on a certain railcar type.

- A certain train path is only used with certain types of railcar (e.g. suitable route classes, see below).

- A certain business partner may only use certain railcar types.

In addition, the general dimensions and weights of the vehicle (vehicle resource or equipment) and the specific axle loads are taken into account in load consolidation. Furthermore, a condition can be used to determine the route class based on receiving stations and border stations, and the respective means of transport (railcar type with adjusted capacity for the respective route class) can be taken into account for planning so that the individual railcar is not overloaded.

After load consolidation, you can use the VSR optimizer in the Transport Cockpit to plan the railcar unit for a freight order.

Triangulation and follow-up transports

A topic we come across again and again, especially in the case of our own railcar stock, is railcar triangulation. This includes the return and provision of empty railcars. The triangulation functionality exists for this, which intermarries an empty container supply railcar unit and an empty container return railcar unit into a triangulation railcar unit. This new railcar unit covers both stages and has the movement category Triangulation.

If the cargo (for example, a container in intermodal transport) is only brought to a terminal by truck in the course of a preliminary leg, the follow-up transport functionality in SAP TM is also recommended. The subsequent transport functionality can chain several freight orders (rail and road) to each other or form round trips.

Adaptive processes with SAP TM

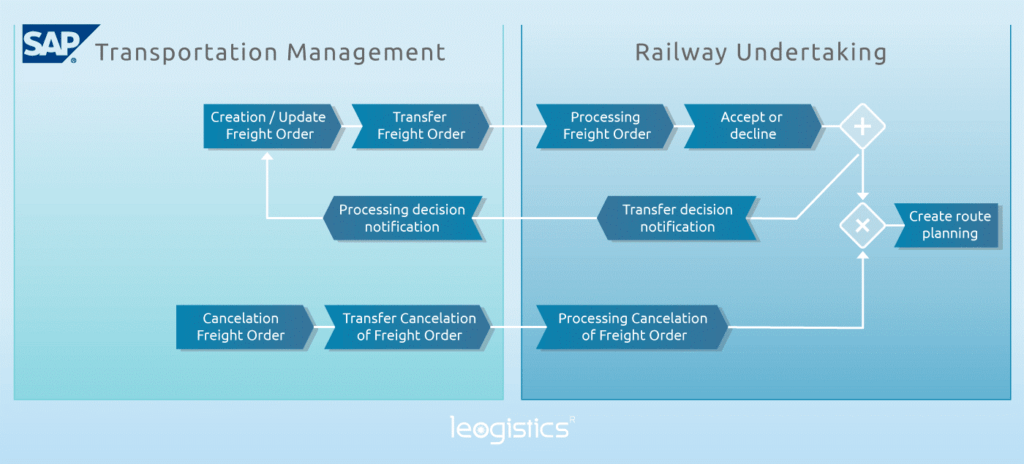

The integration with the rail transport company takes place on the basis of the rail freight order. A rail freight order consumes either freight units or railcar units depending on the scenario. An RU is assigned to this rail freight order. Web services can then be sent to the RU via EDI. SAP TM uses a Web service for transmission. available:

- TransportationOrderRequest_Out = the outgoing message

- TransportationOrderRequestConfimration_In = the confirmation of the carrier

- TransportationOrderRequestCancellation_Out = the cancellation

The messages are mapped to the messages of the RUs via a middleware. Our experience has shown that the SAP TM standard is not sufficient here. We have therefore extended the SAP standard at this point to meet the requirements of Deutsche Bahn, for example. The Deutsche Bahn has among others the following messages:

- IFTMIN is an EDI message format for the transmission of the electronic freight order. In this format, the order data is transmitted, and pre-booking and completion of orders is carried out.

- IFTMAN is used to pre-register order data and to confirm order data.

- The IFCSUM format transmits train data and railcar order of the incoming train. This message corresponds to an electronic train pre-registration. The IFTSTA data format is used for information on the start of the shipment, track & trace, and completion of the shipment.

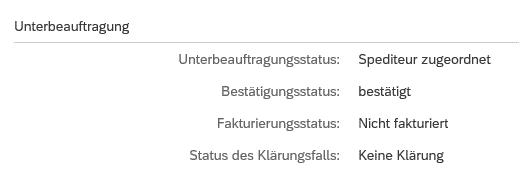

The result of the acceptance of the order can be found on the rail freight order tab Status.

Contrary to this, the IFTSTA data lands on the Execution tab in the form of events.

What's next?

Now that we have looked at some basics of configuration and master data and the possibilities of routes and optimization, we will deal with reporting and billing via SAP TM in the further course of the blog article series.

Did we arouse your interest? Then follow our blog series or contact us directly.

If you have any questions about this or other blog topics, please contact blog@leogistics.com.

Nina Mallien

Matthias Platzer

Alexander Regin-Lück

Consultants SAP Logistics