How sap TM takes over the packaging planning and thus enables optimal load planning

A successful load planning of trucks and containers includes the consideration of legal and physical (e.g. axle load) restrictions. Special cases must also be taken into account, such as avoiding broken pallets.

We have made the experience with many customers that the load planning takes place long before the creation of the picking (and thus the provision of shipping pallets). This process flow is also quite logical, since a certain lead time is required to organize the shipments, for example, for the selection of a forwarding agent or a freight tender.

The difficult task of the planner

From the planner’s point of view, sales orders rarely consist of 34 full pallets for a truck which are all going to the same shipping address address. It is more realistic to load a swap body with goods for several customers. These can be on full pallets or mixed pallets.

Especially when customer orders contain several products in different quantities, it is very unlikely that solid loading space planning will take before the warehouse provided feedback of the picking results.

The goal of packaging planning

But such an early and precise planning is needed to use loading space effectively, save costs and conserve resources. For this usecase, SAP offers the SCE Package Builder function.

Based on settings and product master data, SAP Transportation Management plans which products are packed in which quantities on which pallets during the creation of freight units.

This result is transferred to SAP EWM, where it is used as a packaging material proposal (planned shipping handling unit).

At the same time, this detailed planning of shipping units provides a very good starting point for the loading space planning of your trucks, containers, or swap bodies.

What does the sce package builder do?

If the Package Builder is triggered during a freight unit creation, the following logic is executed:

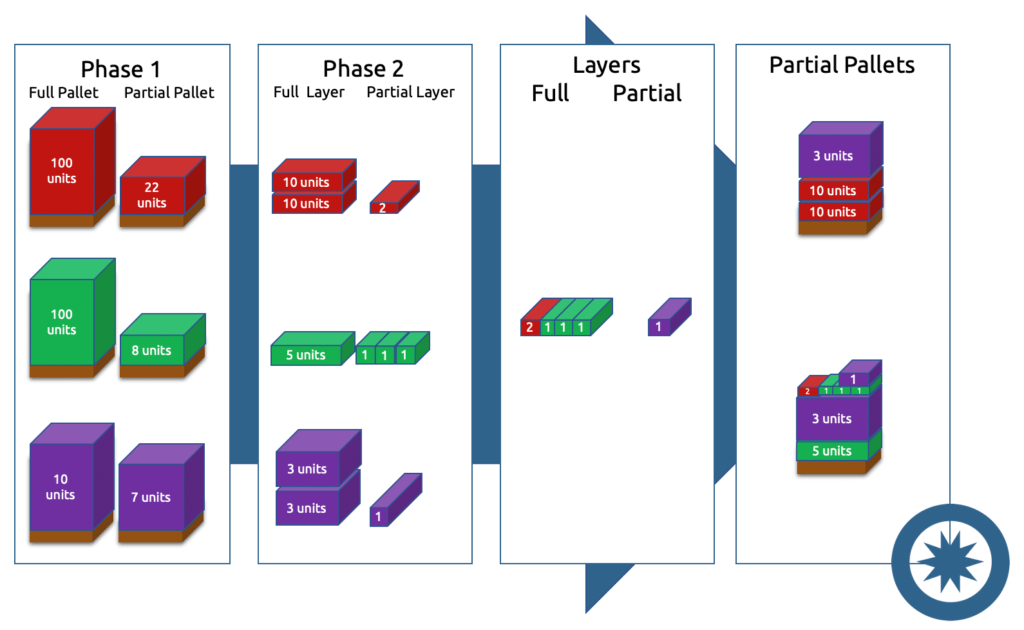

- The Package Builder uses an algorithm that divides the delivery quantities into article-pure full pallets and “remainders” (phase 1 in the diagram).

- When the remaining quantities are processed further (phase 2 in the diagram), the Package Builder algorithm checks in the article master data how many products correspond to a whole layer – that is, how many fit on a pallet without stacking. The remaining quantities created previously are thus further subdivided into the subset’s layers and pieces.

- The Package Builder plans the entire layers of the various products on mixed pallets. It stacks layers on top of each other until a restrictive requirement is reached, such as a maximum height, a maximum weight or a maximum number of different products.

- The algorithm selects individual products with a similar height from the remaining pieces and attempts to combine them into mixed layers. A similar height allows to put on more mixed layers.

- Remaining quantities that cannot be planned in any mixed layer are placed by the Package Builder as “loose goods” on the topmost layers of the mixed pallets.

Thus, the SCE Package Builder in SAP TM creates a certain number of full and mixed pallets, which serve as a planning basis and can be sent to the warehouse management system as picking specifications.

Integration into your logistics processes

One advantage of the SCE Package Builder is the easy integration into existing SAP processes, as the function can be executed automatically in the background. The preparatory work is also manageable.

A suitable Package Builder profile is created in Customizing, which includes some input variables (for example, rules and restrictions) for the algorithm and is started on a process-specific basis using the freight unit creation rule.

Control parameters for the package builder

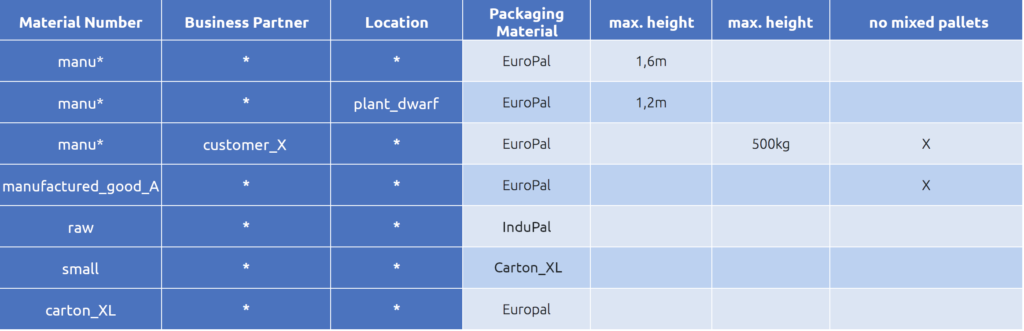

As a further preparation, products must be assigned to package types. In the corresponding table, various packing specifications can be made using the key fields “Product number” “Business partner” and “Location”.

Your mixed pallets for a certain customer should be a maximum of 1.5 m in height, while all other customers receive 1.8 m? When certain products are shipped, should they be on industrial pallets instead of Euro pallets? You control these special features by maintaining a table (/SCMB/V_PPTA).

Which configuration is found?

From the table above, the algorithm always searches for the most suitable entry for a given case. All products starting with the designation manu are planned on euro pallets and have a maximum height of 1.6 m. However, if the same products are shipped from a specific plant, the products are only stacked up to a height of 1.2 m.

This leads to more euro pallets and thus to a different planning basis. Here, you can also maintain that a special customer does not want to have mixed pallets because, for example, he does not want deconsolidation in his goods receipt process.

It is also possible to create a hierarchical packaging structure in which products are planned in boxes and then on pallets.

If the Package Builder is activated when a freight unit is created, it draws the corresponding profile and checks which table entries are relevant for the case at hand. If the product master data is maintained correctly and completely, the Package Builder creates packages based on the algorithm presented above. These results are distributed from the SAP TM system to a connected SAP EWM system as plan shipping HUs using the standard Web service TransportationOrderLoadingAppointmentNotification.

There, this information is used when creating picking tasks or warehouse tasks.

Advantages for your supply chain

This function provides the SAP TM system with a very good information basis for transport planning.

If there are discrepancies between the planned packages and the actual pallets during the process, which can happen again and again due to the “human creativity” factor when stacking mixed pallets, EWM informs the TM of this in turn. To do this, the systems use the standard service TransportationOrderLoadingAppointmentNotification, which is also used in advance for plan data transfer. This notification is important because the EWM system is always the leading instance in the entire packaging process. By using the Package Builder correctly, your TM system can already perform important preparatory work.

Why should i use the package builder?

In summary, the following benefits for your company can be achieved by using the SCE Package Builder:

- It provides a suitable basis for carrying out vehicle resource-specific loading space planning using the SAP Load Planning function. In this way, maximum weights and axle loads can be taken into account on a case-specific basis, and the appropriate number of pallets can be determined.

- It enables you to save transportation costs by planning transportation early and accurately.

- Customer-specific requirements are also taken into account, by simplifying load securing with evenly packed mixed pallets.

Have we caught your interest? We would be happy to advise you in detail on the topics of packaging and transport.

If you have any questions about this or other topics on the blog, please contact blog@leogistics.com.

Frank Meier

Consultant SAP Logistics