Using MQTT and IoT-devices to gain an advantage in your logisitic processes

If you’re considering the use of IoT sensors to automate processes or make digital information available in real-time, it’s good to know you have a variety of options in the open source area.

In today’s post, we’ll examine popular IoT scenarios being used in plant logistics that have surprisingly low implementation costs and big benefit potential. In addition to application examples and information on technical integration, we’ll also let you know about a few of the hardware and software components we currently use today.

Application experience: Smart loading points

To help reduce waiting times of trucks at plant sites, operation managers can benefit from tracking arrivals and departures in real-time. With the help of sensors, IT systems can recognize whether a dock door is currently free vs. occupied. As soon as a dock door or loading point is free, the system can notify the next waiting truck driver, so they can quickly proceed to their delivery location.

What sensor technology should we use?

There are many things to keep in mind when choosing the correct sensor for your use case. In our smart loading point example, we’ll need a distance sensor.

- The distance to the trailer is a primary concern for sensor selection—not all sensors perform particularly well with short or long distances.

- The surface properties of the trailer must also be noted, flat vs. angular, etc.

- The color and reflection properties of the trailer also play an important role. While white lacquer surfaces reflect the red light of a laser very well, black, or matte surfaces can cause issues due to their high absorption capacity.

Laser and ultrasonic sensors and features

Laser and Ultrasonic sensors can be equally suitable for detecting a truck at a loading point. Ultrasonic is a non-optical method in which the color and reflection properties of the surface do not play an important role.

In ultrasound, only the orientation, or distance to the object is important; therefore, ultrasound must hit a straight surface from as far as possible at a right angle, so that the reflection of the sound is optimally directed back to the sensor.

The right choice depends primarily on the installation options at the loading point. Can the sensor be installed at the right distance from the object, at the right angle? Aside from laser and ultrasonic, there are few other options, often more difficult to install and maintain.

Additional use cases for sensors

There are many instances in which farms or warehouses are beginning to use sensor and IoT technology. In these cases, environmental variables can be picked up, processed, and operated by sensors, leading to an increased adoption of more digitized, automated processes.

For example, temperature sensors can be integrated quite easily into the IT landscape. Measurement data can be used for quality checks, which, if outside of control limits, can generate alerts. It’s also possible to check temperature during the execution of loading activities.

Often, the same smart sensors can also measure air pressure and humidity, with many new use cases showing up in the manufacturing and bulk solids industries. Motion and inclination sensors are being used in mechanical and plant engineering to identify accidents. If a critical event has been reported, a check of the system can be enforced to help meet quality standards.

The evolution of raspberry pi and industry automation

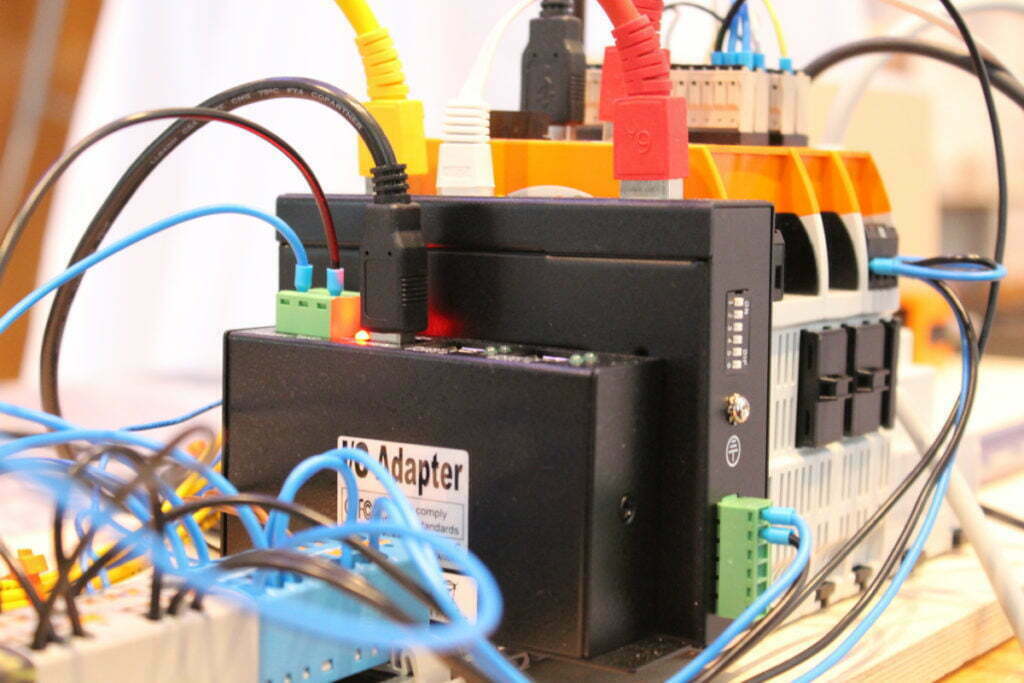

In one of our latest prototypes, the center piece is a “Revolution PI” (vendor Kunbus). The Revolution PI is an industrial device based on raspberry PI with Linux, which is very popular in applications used in home environments.

The Revolution PI is modularly expandable to a full-fledged PLC. In this way, modules for reading and writing digital and analog signals are readily available for quick “plug and play” implementations. The Revolution PI has software installed that analyzes, processes, enriches, and forwards sensor data.

IO-Link

When distributing data from the sensor, we rely on a new technology called IO-Link. For instance, an “IO-Link master” (vendor ifm) can intercept sensor data. The communication is not done directly with the sensor, but via the IO-Link master, which detects and can structure the data. Data is then processed in the IO-Link master and transmitted to the Revolution PI via IoT interface over local or cellular networks.

The IO-Link master also allows operation and data evaluation of sensors without an IO-Link. However in that case, remote parameterization is not possible, and must be completed directly on the sensor.

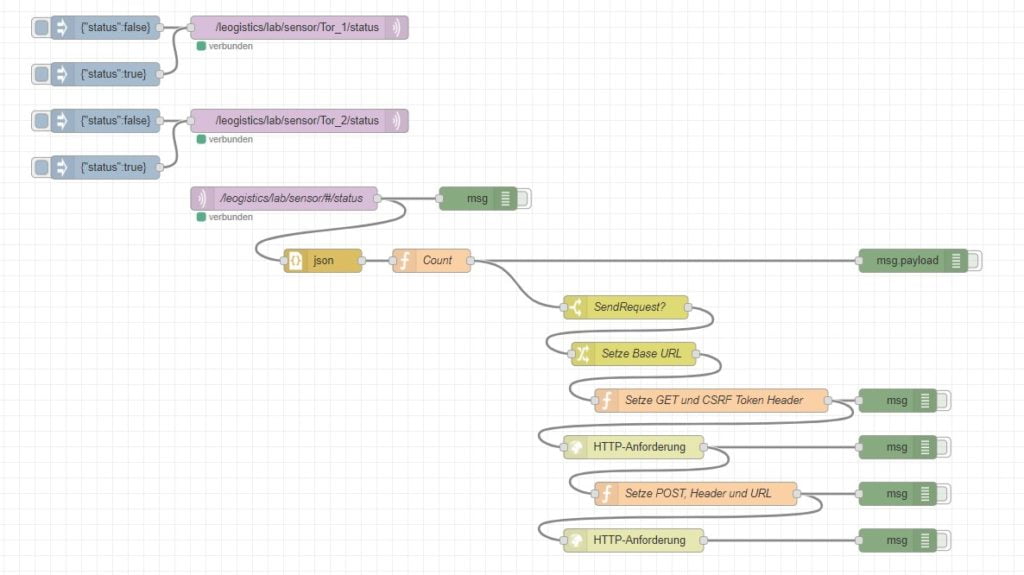

Modelling using node-red

In terms of software for integrating sensor data and controlling sensor logic, we use an open software called “Node-RED”. Node-RED is a graphical development tool that implements use cases in a modular principle. Node-RED can be used to create object process flows, as shown below. With these flows, the data is evaluated and enriched using small functions.

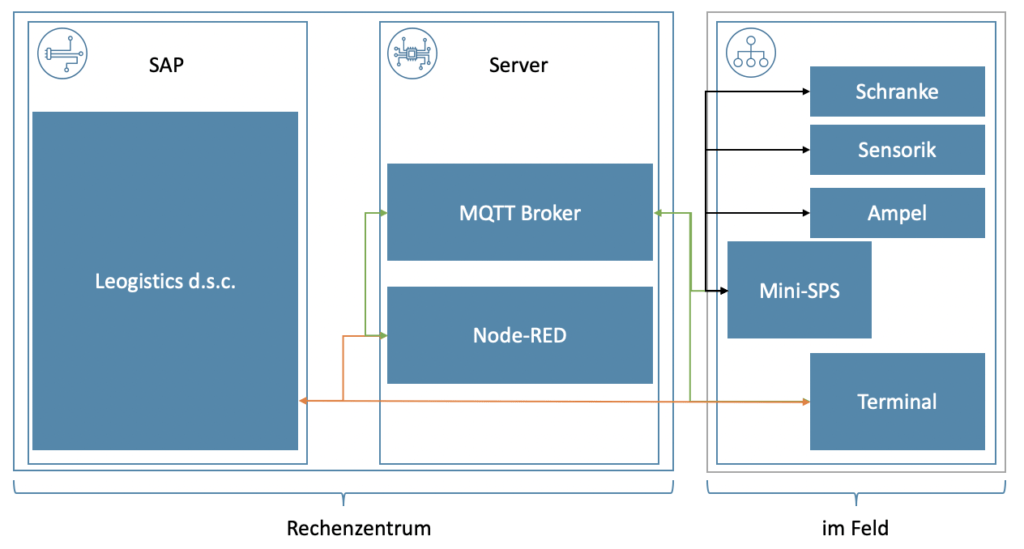

Harmonization using MQTT

For data transmission, we rely on the MQTT protocol, which is widely used in the IoT area. This is an open message protocol for machine-to-machine communication. It allows the transmission of telemetry data, despite high delays or limited networks. Node-RED intercepts the data via MQTT input channels, processes it, then forwards via MQTT to subsequent flows, or ultimately through OData to the SAP system.

Communication with SAP systems

Node-RED speaks not only MQTT, but also the http protocol. This is the basis for web services and REST protocols like OData. SAPUI5 applications are typically connected to SAP systems via OData. Thus, Node-RED can be used to make data from the sensors known to the SAP system, which can trigger follow-up actions, update SAP objects, or create alerts to users.

What's next?

Now we’ve made it to the exciting part, our IoT devices can communicate with SAP. From here, we can trigger actions (for example, loading point traffic light turns green once the truck has driven away) or store bulk data. Using this data, we can start to develop smart services— helping to optimize enterprise processes, make predictions with machine learning and AI, or even create a digital twin.

The digital supply chain vision

Today, we highlighted just a few of the possibilities using inexpensive hardware and software in the IoT space. We hope this post was thought-provoking, leading you to consider opportunities in your own logistics processes.

So…what’s your use case? Would you like to start an IoT prototype? Let us know how we can help!

If you have any questions about this or other topics in the blog, please contact blog@leogistics.com.

Steven Klein

Hendrik Hilleckes

Senior Technical Consultants