More efficient plant rail operations by means of intelligent measuring systems and valuable real-time information

Even to this day, the dispatching and managing of freight trains is often organized manually with paper, lists, by telephone and via isolated systems that are in many parts obsolete.

But we should no longer close our eyes to the digitization of rail freight transport. It is indeed quite true that the transformation of the transport sector is a mammoth project. Yet now more than ever, the chances of achieving future security are promising: Enormous subsidies are available to achieve CO2 savings and thus meet the ambitious climate targets. Let’s take a look at potential solutions.

Paving the way to the future: the digitalization of plant and connecting railroads

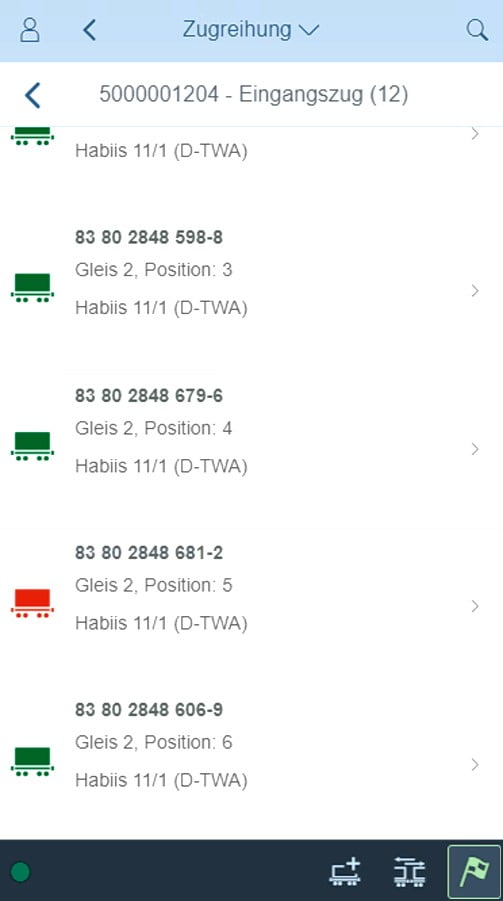

Oftentimes, processes can become more efficient and cost-effective once they are managed through the right software. The SAP-based solution leogistics Rail digitizes the process planning of rail transports, enabling smoother control of everything from incoming train handling to train dispatching. A combination of desktop applications for office staff and mobile apps for the crew on the tracks makes the communication flow faster and more transparent for everyone involved. This involves the use of mobile apps for checking train arrivals and train queues, as well as a shunting app that can be used via smartphone, tablet or a device installed in the traction unit.

A digital edge through smart cooperation

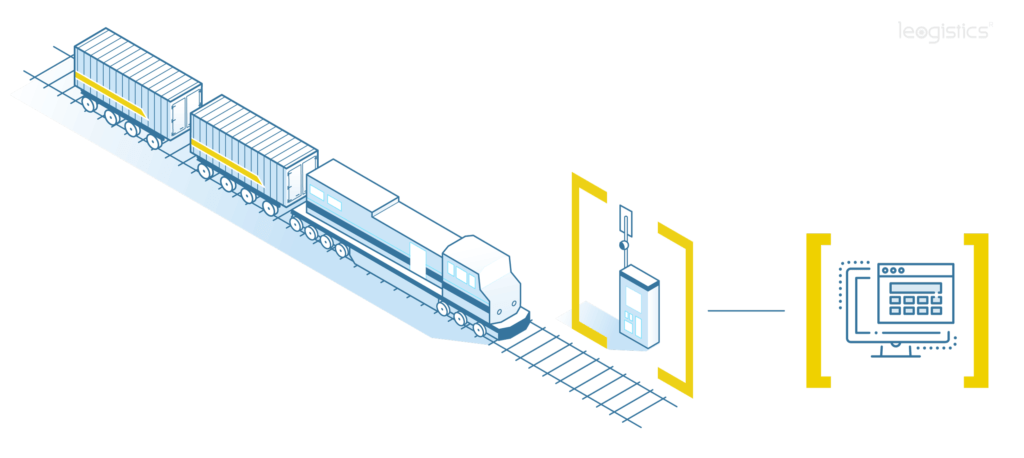

Process control of freight trains is made even more efficient by combining two technologies. Through the integration of RailWatch into the leogistics Rail dispatching software, additional data can be generated via interface for train arrival handling and train dispatching. That is Industry 4.0!

“The integration of RailWatch data in leogistics Rail enables a new process optimization and leads to savings of resources and a cost reduction in the process” says Michael Breuer, managing partner of RailWatch GmbH & Co. KG.

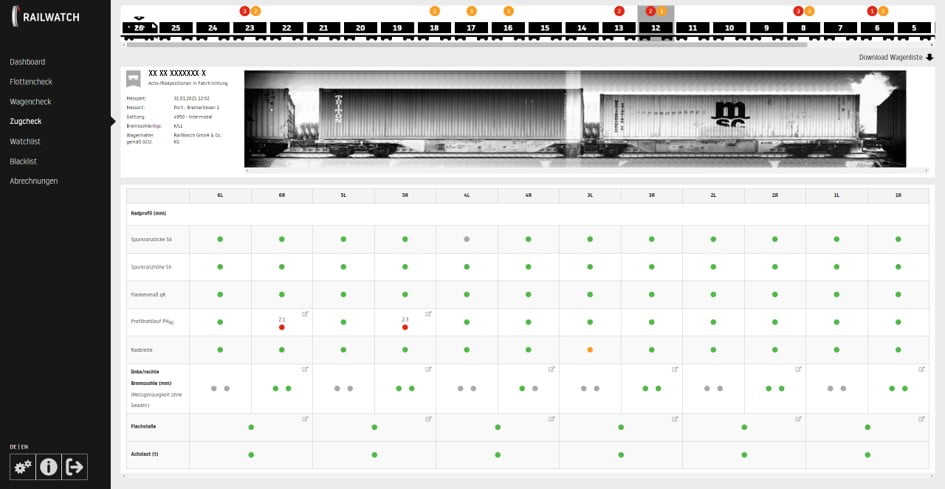

The RailWatch system uses its own “Pulsar” measuring system to record information on wagon queuing, wagon conditions, speed, wear, undesirable wear and tear and other damage at the respective industrial entrances. In addition, RailWatch has further stages at main traffic corridors and port entrances, which map an intelligent station network via a connection to the cloud. This data can also be included in the interface, depending on customer requirements. RailWatch is a software-as-a-service (SaaS) provider that generates and sells data using its own technology.

Incoming train handling - automated identification of wagons

The incoming train handling is of utmost importance in the process handling. Automatic trolley identification enables smart handling of incoming trains.

leogistics Rail compares the received RailWatch data with information from existing datasets such as timetables and train pre-announcements. If the RailWatch data matches the train pre-announcement, leogistics Rail issues a success message. If there is no match of the reported data, the tool generates an error message and automatically adjusts the wagon list by the RailWatch data.

As a result, the process of handling incoming trains can be supported digitally. People responsible for the train journey do not have to manually match the car list by walking the entire train, but automatically receive the correct car list thanks to the data collected on arrival.

This also applies to train arrivals without train pre-announcement. If no train pre-announcement is available, the wagon information from the measuring system automatically provides the data basis for the incoming train. The result: a complete wagon list and a correct position of the wagons in the train set.

Transparency for data integration into one system brings great benefts

Physical shunting in particular is one of the main sources of efficiency losses in factory railroad operations when suboptimal planning and execution are involved. Proper interaction between people and technical innovations simplify the processes of automated car recognition.

One example: Before freight cars enter the rail yard, the localization and status information from the RailWatch measuring stations is transmitted to leogistics Rail, processed, and taken into account so that shunting procedures can be implemented as efficiently as possible.

Using the additional status information from RailWatch, defective wagons can be directly taken into account and sorted out in the shunting process. This promotes the shunting process by eliminating the need for an additional shunting cycle to remove the defective wagon. The faulty wagon is thus not reloaded from the start, which means that the costly reloading of faulty wagons is no longer necessary.

Digital collobaration improves management and marshalling sequence

The advantages of dovetailing the technologies are obvious: Processes within the software improve through continuous data integration. The system-supported train sequence check leads to:

Acceleration of the input train treatment

Increased transparency and accuracy of wagon information

Processing of additional information, such as wagon markings dangerous goods marking and technical conditions

Reduction in manual effort

Resource saving

Consequently, optimal cooperation between all participants can be established if all process participants have current and relevant data at their disposal at all times. Intelligent communication and data synchronization ensure proactive control processes based on complete information.

It is worth taking a closer look at the area of rail handling. Modern solutions as well as variously available new technologies offer excellent opportunities to massively improve the processes of rail transport in production and loading facilities.

We support you in making your operational rail-bound processes more interlinked, transparent and cost-saving and thus improve your supply chains. Have we sparked your interest? If so, please feel free to contact us directly.

If you have any questions about this or any other topic on the blog, please feel free to contact us at blog@leogistics.com.

Niklas Braun

Consultant SAP Logistics