The basic of rail logistics processes with SAP Transportation Management

In this article we start our rail blog series focusing on resource mapping, wagon planning and document flow. In this blog series, we at leogistics intend to summarize the innovations of SAP S/4HANA Transportation Management in the field of rail-bound transports. In the next articles we will focus primarily on the mapping of schedules, route determination, load consolidation, freight costs and reporting. At one point or another, we will also cross the road to leogistics Rail in order to be able to ensure complete process mapping.

The importance of the railways for the company

In the course of history, the railway was the consequence and at the same time the prerequisite for the industrial revolution. Even today, rail transport is the backbone of an efficient industry. Depending on the economic area, geographical conditions and regulations, rail transport can exploit its advantages over other modes of transport and account for considerable shares of the modal split, i.e. the distribution of the total volume of traffic among individual modes of transport.

However, for a long time this backbone was pushed further and further into the background by the high degree of innovation of other means of transport. Decreasing shares in the modal split were the consequence. For decades, the innovative impetus for the railways failed to materialise. It was not until a reorientation of the cross-border regulations in the EU, an increase in the transport of bulk goods and a general reorientation towards environmentally friendly and sustainable transport that the railways came back into focus in decisions on means of transport.

The renaissance of railway technology

The push for innovation in railway technology, railway infrastructure and railway operation was much overdue. Nevertheless, it took almost ten more years before the IT systems of manufacturing companies (and thus the transport decision-makers at the lowest level) were also geared to the railway as a mode of transport.

The possibilities of SAP Transportation Management

With SAP TM, it is possible to map a digitalized order and freight cost management and thus reduce transport costs while optimizing material and goods flows. For the railway application area this means that we map process-relevant master data for resources, schedules, business rules and freight costs and use it for transport planning, processing and billing. The advantage here is the high degree of integration with SAP ERP or S/4HANA.

The wagon as a mean of transport

The basis for transport by rail is both physically and systemically the wagon. For a long time not even a distinction was made: Wagon was wagon, only the capacity in tons was considered a distinguishing feature.

In the meantime, the system offers a finely tuned subdivision according to the type and design of the railway wagons. The vehicle types are used as templates, which sort the vehicle into a dimension category, for example. Vehicle groups and vehicle types are maintained with the corresponding dimensions and weights in Customizing. In transportation planning and load consolidation, the means of transport and vehicle types are used to run checks (for example, whether or not certain freight units can be loaded onto a means of transport).

Restrictions that arise here are subsequently mapped using incompatibilities. Additional capacities can be depicted using compartments, which are assigned to vehicle resources and vehicle types using profiles. Appropriate vehicle resources are created for each vehicle type.

Whether open or covered, refrigerated wagon or flat wagon, tank wagon or special design: every type of wagon is correctly recorded systemically. This enables the transport planner to make decisions on the equipment group or equipment type level, whereas the wagon deployment planning even has access to individual rail wagons (resources).

The wagon unit

The allocation of freight to wagons is done with the help of so-called wagon units. TM offers the basic function of transferring transport requirements from SAP ERP to TM and mapping them in the form of divisible freight units. The wagon unit is a further development to a pure freight unit: If the transport decision is made for the railroad, a wagon unit can be created directly instead of a freight unit.

This has the following advantages:

- Wagon units represent one or more wagons; the production types single wagon, wagon group and block train are supported.

- Several main items can be entered in the wagon unit (for example, if a mixed loading of wagon groups or block trains takes place).

- The wagon unit is divided into (transport) sections. The individual sections of the wagon run can be assigned to several rail freight orders. In this way, transport chains of individual wagons or the traction of block trains by different rail transport companies can be reflected in the system.

Components of the wagon unit

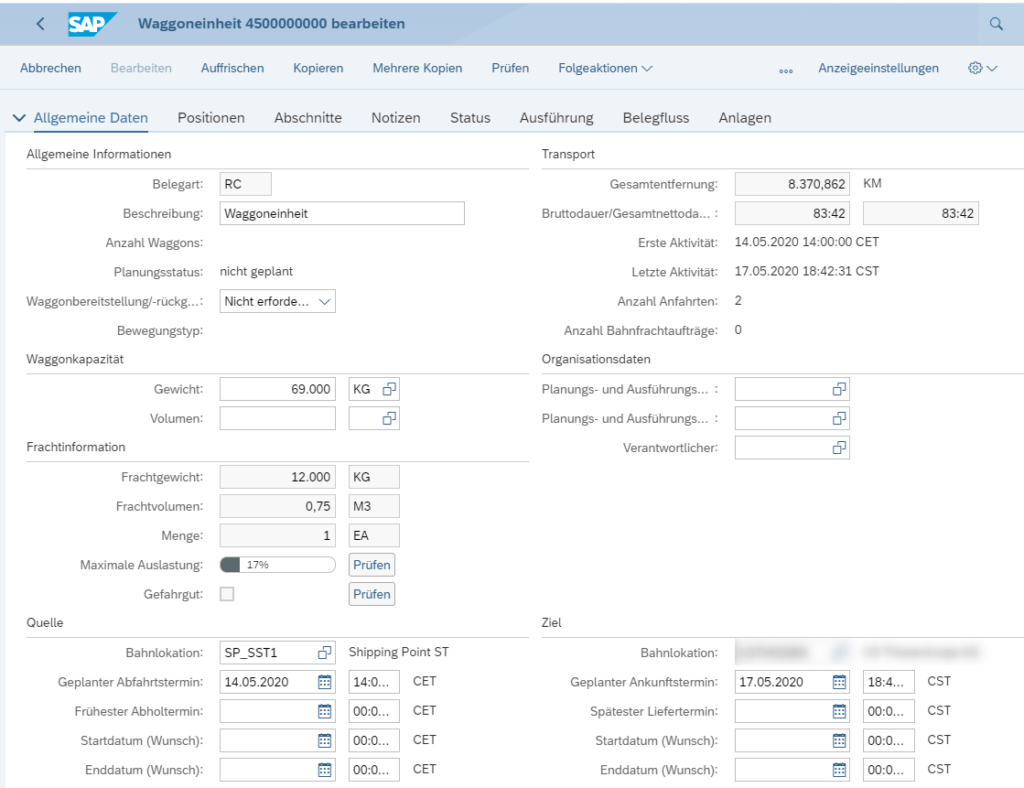

General data

In the tab “General data” the transport planner finds general information on the document type, the number of wagons, the planning status and the wagon provision. Further information is included on the wagon capacity (as weight and/or volume) and the freight (freight weight, freight volume, quantity, utilization in percent and dangerous goods). Information on the shipment (total distance, gross duration, and so on) is also visible. The source (start location) and destination (destination location) of the shipment with the planned departure or arrival date and time can also be viewed.

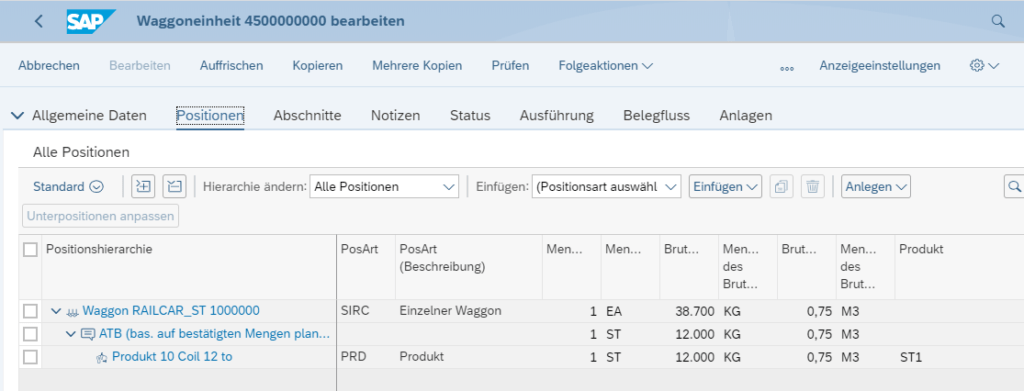

Positions

The tab “Items” reflects the loading of the wagon unit and is divided into the hierarchy Wagon > Transport requirement > Products.

Sections

The tab “Stages” lists the shipment stages from a source location to a destination location. As mentioned at the beginning, a wagon shipment can have several sections in single wagonload traffic or a block train is tractioned by different executing RUs. Each break in the transport (marshalling yard or traction change) is reflected in the system by a section. This enables detailed planning of the entire transport chain including the timetables stored in the system.

The transport chain can be built up with the following section components:

- Source location (= start location) [shipping point].

- (Earliest) requested pick-up date and time [time of earliest possible dispatch after loading of the wagon].

- Planned date and time of departure [time of scheduled departure of the service trip at the loading point or scheduled departure of the train from the dispatch station].

- (Latest) requested delivery date and requested delivery time [date of the latest possible acceptance of the wagons by the consignee].

- Planned date and time of arrival [time of scheduled arrival of the service at the destination station or scheduled arrival of the train at the destination station].

- Forwarding Agent [operating railway undertaking]

- Planning status

Statusübersicht

The tab contains various transport and document-specific status information

Life cycle status

| Status value | Trigger |

|---|---|

| New | This status is only relevant when the wagon unit is created manually |

| In process | Status is set as soon as the planning of the wagon units has been carried out and remains active, until the transport execution has been completed or the settlement of the wagon unit has taken place |

| Completed | Once the billing status "fully billed" has been set |

| Cancelled | Wagon unit was cancelled |

Planning status

| Status value | Trigger |

|---|---|

| Not planned | The transport section has not yet been planned |

| Planned | All transport sections are planned continuously |

| Planned, conflicts between freight unit and freight order/booking times | The shipment stage is planned, but time conflicts have occurred in the train run or in the transport chain (with regard to predecessor and successor shipment stages) |

| Not ready for planning | There are no railway stations in the transport chain, the wagon unit cannot yet be planned |

Load plan status

| Status value | Trigger |

|---|---|

| Not planned | Initial status, before planning |

| Not relevant | Planning is not relevant for this shipment stage |

| Disabled | Changes in the loading plan (there have been changes at item level) |

| Planned | The planning is provisionally completed, but the plan can still be updated |

| Completed | The planning is completed |

Execution status

| Status value | Trigger |

|---|---|

| In execution | The bills of lading were created and the transport of the wagons was started |

| Executed | The transport is completely finished, the receiving railway station has reported the arrival. |

| Cancelled | The transport or the train run has been cancelled |

Delivery status

| Status value | Trigger |

|---|---|

| Not delivered | The wagon unit has not yet been delivered to the receiving railway station (or the receiving loading station) |

| Partially delivered | The wagon unit was partially delivered. This status occurs, for example, for wagon groups if individual wagons have only been delivered to the entire group |

| Delivered | The wagon unit was delivered to the receiving railway station |

The tab “Status” also shows whether a planning, execution or billing block exists for the shipment stage.

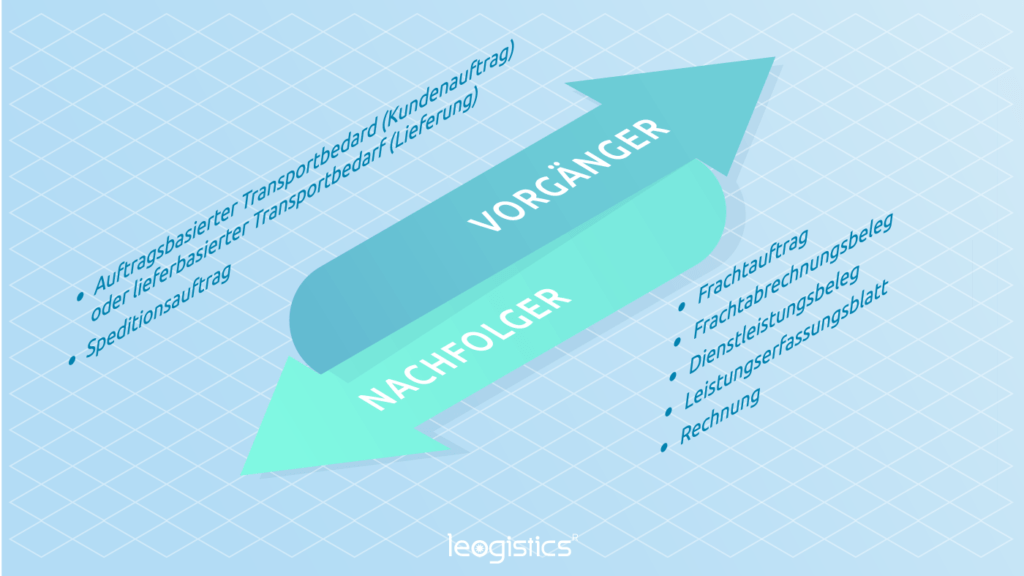

The document flow in SAP TM

In SAP it is common practice to create an overview of the document flow across all systems involved. In the wagon unit, all preceding and subsequent business documents for the shipment are displayed on this tab page. The following hierarchy is available to the transportation planner.

A jump to upstream systems or to subsequent business documents is thus possible at the click of a mouse.

The outlook

With the mapping of wagons and wagon units, we have laid the procedural foundation to go into the special features and innovations in the field of rail-bound transport with SAP TM in the following.

Have we aroused your interest? Then follow our blog series or contact us directly.

If you have any questions about this or other blog topics, please contact blog@leogistics.com.

Nina Mallien

Matthias Platzer

Alexander Regin-Lück

Consultants SAP Logistics